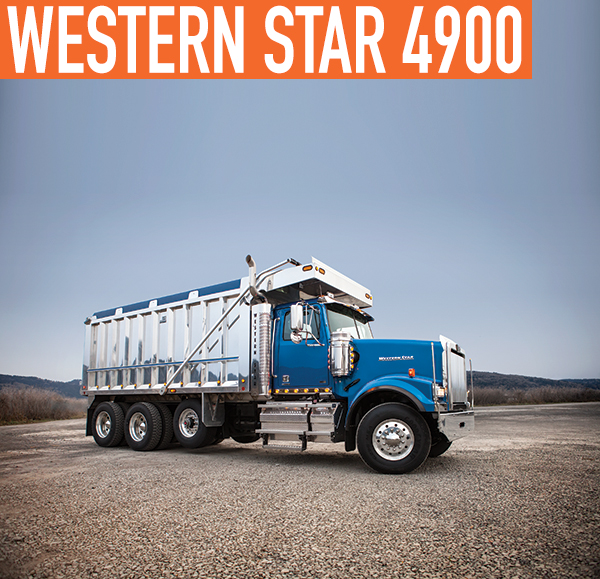

Over the span of a half century, Western Star has introduced numerous models, but the 4900 is a time-tested, solid performer. “Whether you’re looking for a truck to handle business on the highway or off, there’s few out there to match the power, dependability, and durability of the Western Star® 4900,” according to the company. “Starting with our spacious all-steel cab and built with an incredible array of rugged, long-lasting components, each 4900 delivers incredible value as easily as it does on-the-job performance.”

CAB OF STEEL

The 4900’s galvannealed steel cab is bonded, precision welded, and protected with a multi-stage e-coat process that provides long-lasting corrosion resistance. The 4900’s custom-pierced frame rails eliminate unnecessary holes, while shot-peened frame rails improve strength, longevity, and durability. With its easy-opening, 90-degree tilt hood with spring assist, threaded spring pin, and standard Grade 8 fasteners, the 4900 allows for easy maintenance without sacrificing strength.

The 4900’s double door seals and standard insulation package reduce noise and improve climate control efficiency. With air and electrical lines suspended away from the frame rail to prevent failures from debris buildup and in-cab electrical panels—preventing corrosion and possible damage—the 4900 is designed for endurance.

A few optional features for the 4900 include:

- A heavy-duty hood pivot option that resists twisting and contributes to longer component life

- A wide range of tilt fiberglass hood options, ranging from classic to sloped

- Optional all-bolted crossmember construction for increased reliability, durability, and ease of replacement

- Five-piece heavy-duty C-channel crossmembers with ⅜-inch gussets, available for severe-duty applications

- Optional spec’ing up to triple frame rails for the heaviest loads

- Clean back-of-cab options for faster, easier body installations

- Engine- or frame-mounted radiators designed to keep the engine at operating temperature to maximize fuel economy and prolong engine life

SATISFYING POWER

According to Western Star, “Front engine PTO or rear engine PTO, we have you covered. Versatile, efficient, powerful, and dependable. There’s no shortage of getting what you want around here.” When you get a 4900, you’re sure to get it equipped with the engine that’s right for your needs. Western Star’s range of engine options includes:

- The Detroit™ DD13®, providing 350 to 505 hp and 1,350 to 1,850 lb-ft of torque

- The Detroit DD15®, providing 400 to 505 hp and 1,550 to 1,750 lb-ft of torque

- The Detroit DD16®, providing 500 to 600 hp and 1,850 to 2,050 lb-ft of torque

- The Detroit Series 60® TIER III, providing 425 to 500 hp and 1,475 to 1,550 lb-ft of torque

- The Cummins® ISX15, providing 400 to 600 hp and 1,450 to 2,050 lb-ft of torque

FACTORY CUSTOMIZATION

Western Star works to make sure the truck you get is the truck you need. With such factory-installed options as twin steer chassis, lift axles, and all-wheel drive, you can bet your 4900 will be customized to your needs. “These OEM options are specifically designed for our trucks, so they not only save you time and money, they’re fully covered by your factory warranty,” according to the company.

Spacious, ergonomically designed interior of the Western Star 4900.

KEEPING TABS

Western Star will back your 4900 with the Detroit Virtual Technician™ (DVT), standard on all Western Star truck models utilizing a Detroit engine. DVT transmits critical engine data and diagnostics and identifies problems—including the severity of the problems—saving time and money. “Should you need service, DVT will direct you to the nearest location with the needed parts in stock,” according to Western Star.

Western Star also offers visibility fleet software, which the company says delivers real-time data on your entire fleet, making it easier to monitor the status of one or all of your trucks. Western Star’s visibility fleet software allows you to quickly audit vehicle location, speed, routes, idle times, and more to help you adjust your vehicles, training, and/or routes.

AMERICAN HERITAGE

With Western Star’s history of ruggedness, dependability, and hand-built factory customization, it’s no surprise that the company’s trucks are still manufactured in the United States. “At both our flagship plant in Portland, Oregon, and our state-of-the-art Daimler plant in Cleveland, North Carolina, Western Star trucks are assembled by hand, using the toughest Western Star components and the most advanced Daimler technology available. It’s not the least expensive way to build a truck, but it is the Western Star way.”

FOR MORE INFORMATION:

Western Star is a subsidiary of Daimler Trucks North America LLC. Daimler Trucks North America produces and markets Class 5 through 8 vehicles and is a Daimler company, the world’s leading commercial vehicle manufacturer. Find out more about Western Star products and services, visit www.westernstartrucks.com.

_______________________________________________________________________

MODERN WORKTRUCK SOLUTIONS: OCTOBER 2016 ISSUE

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern WorkTruck Solutions magazine.

![]()