Whether their objectives are to comply with state, county, and local idling laws, or to exhibit forward-thinking corporate citizenship, fleets increasingly have the topic of idle mitigation on their minds. Part of what concerns these fleets is the question of how they will continue to get the requisite amount of work done in this new no-idle or reduced-idle environment.

Add to the equation the pressure that many fleets face to replace significant populations of their internal-combustion-engine (ICE) vehicles with electric vehicles, and you have a recipe for high anxiety. Not just the “range anxiety” that has always been a concern associated with EVs, but “work anxiety” related to whether their EVs will have the power to get to the jobsite, do the work, and get back to home base.

“Having served the mobile power marketplace for just over half a century, we’ve helped fleets address evolutionary changes all along the way, but the rate of change has accelerated beyond anything any of us has experienced ever before,” says Dean Strathman, vice president of sales for Vanair.

Strathman explains that Vanair has a robust voice-of-the-customer (VOC) program in place, and because of that continuous pipeline of real-world feedback, Vanair saw changes on the horizon long before others were even remotely aware they were coming. “And now they’re here,” Strathman muses, “And we’re ready.”

“EPEQ” ADVANCEMENT

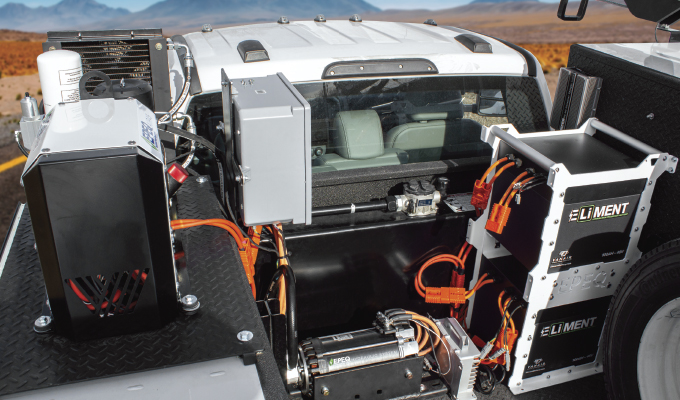

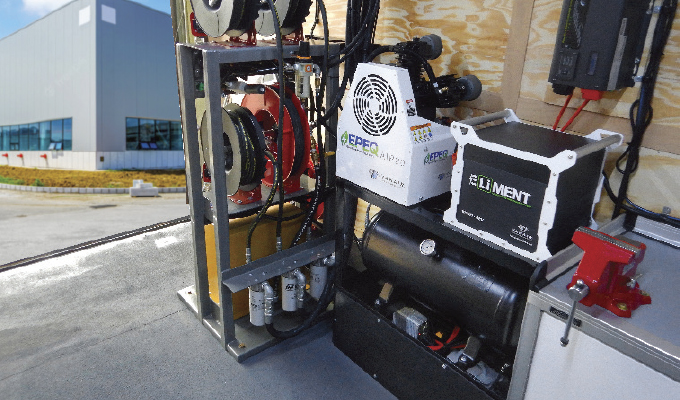

Vanair recently introduced its EPEQ Electrified Power Equipment line, which is an innovative electrified extension of the company’s already broad portfolio of what it has branded as its “Mobile Power Solutions.”

The EPEQ Electrified Power Equipment product line is an end-to-end system offering 100% of the components needed for a complete green technology system. The EPEQ product lineup is designed to put viable electric mobile power solutions in the hand of fleets today. This allows any fleet to immediately reduce its carbon footprint and meet or surpass virtually any state, county, and local idling mandates.

“The reality is that petroleum-driven vehicles will be with us in the field for the foreseeable future, even as their EV replacements continue to come online,” says Sara Tilden, vice president of marketing for Vanair. “Our EPEQ line of solutions enables any fleet to become a true ‘green fleet’ now, without waiting for the EV revolution to unfold, charging infrastructure issues to be solved, and the rest of the world to essentially shift on its axis.”

The EPEQ product offering includes a variety of practical, fully-electric mobile power solutions that can make an immediate impact on a fleet’s carbon footprint.

THE EPEQ LINEUP

The innovative EPEQ line of purpose-designed products includes:

- ELiMENT brand lithium iron phosphate (LiFePO4) battery

- Smart Controller

- ePTO brand electric power take-off for cranes, booms, and other hydraulic equipment

- Electric-motor-driven reciprocating, rotary screw, and oil-free air compressors

- AC power inverters

- Welders

- Level 1 and 2 EV charging

- Idle mitigation

- Alternators/regulators

- DC-DC converters

Each component in the EPEQ line is purposely designed and optimized to work within a battery-powered system. The advanced ELiMENT LiFePO4 Battery contains a one-of-a-kind battery management system (BMS) that has the ability to discharge power while being charged itself.

The EPEQ Smart Controller has proprietary software technology designed to intelligently monitor and control all the components in the system. Each component can communicate signals to and from the controller’s board allowing battery power supplied to be adjusted based on a range of factors such as: temperature, heat buildup, duty cycle, assigned function priorities, and power remaining.

With the EPEQ line’s breadth of functionality, Vanair has the ability to tailor a system to meet the needs of any fleet around. Depending on the form(s) of power a fleet needs, a targeted, single-function machine can be ordered, or an “ecosystem” product grouping kit, combining just those functions needed for a specific fleet’s applications, can likewise be configured.

THE INSIDE SCOOP

EPEQ is a fully self-contained and independent system that can be mounted on or within ICE vehicles, electric vehicles, or even on or in trailers. On electric vehicles, it can either work with the host vehicle’s batteries or independently of those batteries.

When installed in a van or enclosed body, users will experience a nearly 60% noise reduction and no exhaust. With the electrified system, maintenance is also greatly reduced and significant fuel savings benefits can be immediately realized.

“The functionality of the EPEQ system has been perfect,” says Frank Wallis, service technician for San Tan Ford. “It’s quiet, there’s no pounding of a loud air compressor. It operates the balancer on our tire machine without issue. There aren’t any CO2 fumes inside the truck, so we can safely retrieve parts. It simply all works; no issues!”

Vanair’s Strathman explained that the company saw early market opportunities with fleets looking for a means to work within an enclosed vehicle space, which would have been impossible before EPEQ because of fumes, noise, and other factors.

A REAL TURNOFF

All EPEQ systems are designed to be scalable, allowing for the addition of different power equipment and now, Vanair’s EPEQ IDLE MITIGATION (EPEQ IM) kit provides fleets with a solution that will automatically turn off a vehicle while still allowing workers to operate the vehicle’s power equipment.

“EPEQ IM can be designed to turn the vehicle on or off based on fleet-dictated parameters such as run time or battery state of charge,” Strathman explains. “The system can employ the onboard vehicle battery or Vanair’s EPEQ ELiMENT LiFePO4 auxiliary battery to power cab heat and air conditioning, emergency lights and strobes, radios, laptops, cameras, and AC electrical equipment.”

The EPEQ IM system that Vanair has developed addresses not only the emission issue, but chassis lifespan extension as well. The Smart Controller module can be tucked away, out of sight, underneath the dash and can communicate through the vehicle’s J1939 CAN bus network or OBD port.

According to Strathman, setting the parameters for the EPEQ IM system is easy. “Examples are: It needs to be in park or to have been in park for a set amount of time; or the chassis’ battery voltage has to be at a certain level. The system has great flexibility,” he says. “Regardless of the settings chosen, once those conditions have been met, the system forces the vehicle off automatically.”

COST REDUCTION

Strathman noted that the term “ghost miles” is being used in the industry right now. He suggests that the rule of thumb is that every hour of idling time is the equivalent of approximately 30 ghost miles of wear and tear.

“When you look at the fuel consumption reduction, at minimizing hours on an engine, and at DPF regeneration and periodic cleaning and replacement, you’re looking at real reductions in maintenance costs,” Strathman says. “When you consider some of these basic factors, it’s really a pretty quick payback for some of these fleets.”

The Vanair EPEQ systems can be paired with Vanair’s new telematics package, adding invaluable asset usage information to fleet managers.

BRIDGING THE GAP

Not only will Vanair’s EPEQ Electrified Power Equipment line help today’s diesel- and gas-powered fleets achieve their carbon emission reduction goals sooner, it will help them through their transition to largely electric vehicles. The system is designed to seamlessly work with all coming electric vehicles and removes the burden of powering truck-mounted equipment from an EV’s primary battery bank.

“Electric vehicles will also be a great fit for our electrified products,” Vanair’s Tilden says. “We can power traditional PTO-driven components … rather than using a PTO driven by the chassis’ engine. Today’s workers using tomorrow’s EVs will be able to operate the same equipment they’re presently using, all without extra training or having to transition to some exotic or novel solution,” Tilden says. “EPEQ makes work simpler and more productive now—and it will keep work simpler and more productive as fleets move into the future.”

FOR MORE INFORMATION

Find out more about the Vanair EPEQ Electrified Power Equipment line, visit www.vanair.com.