By Tom Rice

While many businesses put a halt to their operations during the pandemic, construction businesses remain resilient. Self-service innovations are a staple in keeping essential construction operations going. Software and automation technology can create a virtually touchless supply chain and reduce the need for truck drivers to engage directly with other quarry, plant, and jobsite personnel.

Automation devices and objects with built-in sensors are connected to an IoT platform. A platform can integrate data from each connected device and apply analytics to share the most valuable information with applications built to address specific needs. These powerful platforms can pinpoint useful information or data as well as use the data to detect patterns and problems before they occur. Touchless data can be used in nearly every link in the construction supply chain, starting with sales.

Automation devices and objects with built-in sensors are connected to an IoT platform. A platform can integrate data from each connected device and apply analytics to share the most valuable information with applications built to address specific needs. These powerful platforms can pinpoint useful information or data as well as use the data to detect patterns and problems before they occur. Touchless data can be used in nearly every link in the construction supply chain, starting with sales.

TOUCHLESS SALES

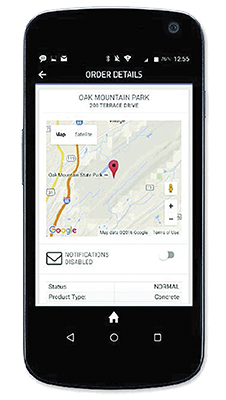

The first step is a mobile app that your sales team can download, enabling them to generate and send quotes directly from the device and then have it sent back to dispatch as a confirmed order. This keeps sales guys in the field and can eliminate inaccuracies while quoting customers. But touchless supply chain extends beyond sales, even venturing into worksites.

AT THE QUARRY

Once orders are ready for pickup, there are many technology solutions that can be implemented at the quarry to enable touchless processes. A scale ticketing system eliminates the common issues of handwritten errors, misplaced tickets, and handwriting recognition challenges. Point-of-sale modules interface directly with the quoting, dispatch, transportation management, and back-office modules to ensure timely and accurate information flow.

An Automatic License Plate Recognition camera further expedites the process for customers by streamlining the entire process, starting with checking in to weighing out with a load ticket. Once on-site, the vehicle is identified in the ticketing system once it passes the check-in ALPR camera. This is confirmed by displaying a “green light” to direct the driver to proceed toward the material loading zones.

A driver can confirm his assignment with the scale operator through radio contact or using an auto check-in lane if repeating previously ticketed job and product information. Once verified, the system will capture the tare weight and communicate the customer ID and target weights to the entire loadout system. The system will update remote displays for the scale operator as well as each customer service loader allowing the view of ticketing information, the required material, and time-in-yard metrics.

The loader operator can use a Wireless Loader program to view all vehicles on-site to be loaded. The program provides all the information needed to load the vehicles from a portable tablet mounted inside the cab of the customer service loaders. After being loaded, the customer’s vehicle proceeds toward the outbound scale where the vehicle’s license plate is reread. The system captures the gross weight and initiates a “green light” for the driver, signaling the load ticket is printing to the remote printer kiosk for their retrieval.

AT THE PLANT

Studies show that the construction industry generates over one million paper tickets per day in the US alone at the cost of over $1 billion per year. Four to five-part tickets are handed out to various departments and individuals on the jobsite. For example, the seller wants a signature on his ticket while the delivery manager will take the ticket as proof of delivery. The buyer receives a part of the ticket and sends it to accounts payable for paying invoices. By the end of the day, one paper ticket has been handled by five or six people—and these same people handle a large number of tickets each day.

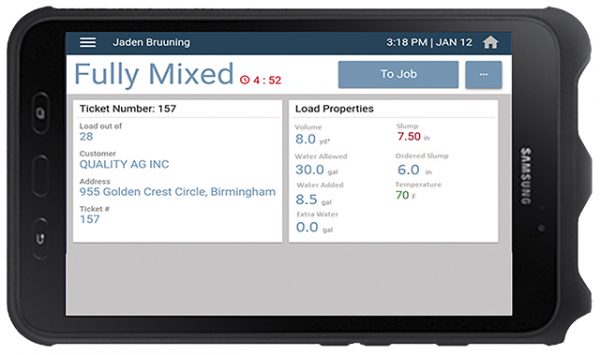

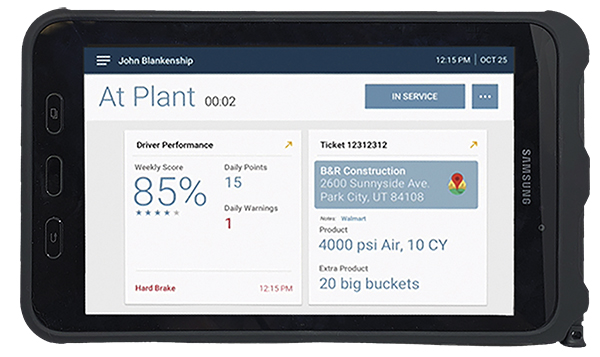

With digitized processes at the ready mix plant, businesses can proactively manage project timelines and costs. With digital processes, reconciling with invoices is quick, easy, and accurate. Even when a delivery is made after hours, the information can still be captured. Without waiting until the end of the day to enter material receipts, batch operators can focus on plant activities instead of managing materials.

Employees can enter data directly into a mobile phone, tablet, or laptop out in the field or when on the jobsite, sending the data directly to business systems in real time. Drivers can receive electronic signatures and use electronic proof of delivery screens. Truck drivers can electronically deliver their information as soon as the materials are delivered, which means invoices can be sent directly to suppliers for quicker payment.

Ticket information is displayed instantly on a driver’s mobile device. Drivers have all the information they need to perform their jobs without having to reach out to dispatch or managers, causing delays in the delivery process. Drivers can pull up their next ticket so they are prepared for their next job.

ON THE JOBSITE

Digital ticketing data enables users to see ticket data in real time, throughout the ticket’s life cycle. Digitalized documentation keeps your guys in the field instead of chasing paper tickets, allowing office personnel to no longer be buried in paperwork and tedious reconciliation processes.

With digital ticket data flowing seamlessly from suppliers to contractors and owners through a Collaboration Platform, the jobsite stays in sync. Having information in one place allows the user to browse orders scheduled for the day and upcoming orders for future days, monitor real-time truck locations and load-level summaries of completed and future orders, receive notifications when a load is on the way, view records of load status times, and automatically match incoming delivery tickets with hauler pay sheets and invoices.

ABOUT THE AUTHOR

Tom Rice is a business consultant and assists with the contractor team at Command Alkon. Tom spent eight years working for Peter Kiewit and Sons in both engineering and construction management roles—from heavy civil transportation projects to oil, chemical, and gas industrial projects. Tom spent five years in the vertical construction world focusing on overall construction management and value engineering and design. Find out more, visit www.commandalkon.com.