Last year, Modern WorkTruck Solutions introduced its readers to the Bollinger Motors B1, B2, and Chass-E. At the time, Bollinger Motors, a brand that’s relatively new to the electric vehicle (EV) manufacturing space, designed and tested prototypes of an electric SUV, an electric pickup truck, and an EV platform that could be used in a variety of work truck applications.

But only a few months after the article ran, Bollinger Motors did an overhaul of its Chass-E design, developing an EV work truck that fits virtually any Class 4-6 vehicle need. Built for work truck applications, the design is powerful, durable, efficient, and versatile.

CAB FORWARD

A major change from its B1 and B2 designs, the B4 Chassis Cab design was thoughtfully executed, and it’s available in Classes 4, 5, and 6.

“The cab-forward design is a radical change from our previous concepts,” says Bollinger Motors founder and CEO Robert Bollinger. “And that’s on purpose. We listened to our commercial customers and developed what they need for ultimate efficiency.”

Those that currently employ cab-forward trucks know the benefits they bring. Cab-forward trucks allow for more cargo space, improved visibility, and they’re easier to maneuver around city streets and tight suburban spaces.

The Bollinger Motors B4 Chassis Cab forward is no exception. Bollinger Motors touts that its cab forward is capable of carrying two extra feet of cargo space compared to conventional work trucks. Cab-forward trucks also don’t have a hood obscuring the driver’s vision, and the result is improved down-vision angles for increased visibility for the road ahead. And the cab-forward design also provides a turning circle that’s only 44 ft (with a 158-inch wheelbase)—making it a great option for operating in congested areas.

EV POWER

At the time of last year’s article, Bollinger Motors developed its own batteries. But in the fall of 2022, Bollinger Motors announced a new battery supplier, Our Next Energy (ONE). ONE builds its Aries LFP (lithium iron phosphate) chemistry batteries without the use of nickel or cobalt. The result is a battery that offers superior durability with a daily charging up to 100%. And further, these batteries are built in the USA.

The 800-volt Aries LFP battery offers a range of roughly 100 miles per battery pack for a range between 140 and 185 miles—and yes, owners can choose the amount of battery packs (either one or two) that work best for their application. The battery charges from 20 to 80% in 4.4 hours using a Level 2 charger or in 1.2 hours when using a Level 3 charger. Additionally, the B4 Chassis Cab powertrain offers 368 hp with 675 lb-ft of torque.

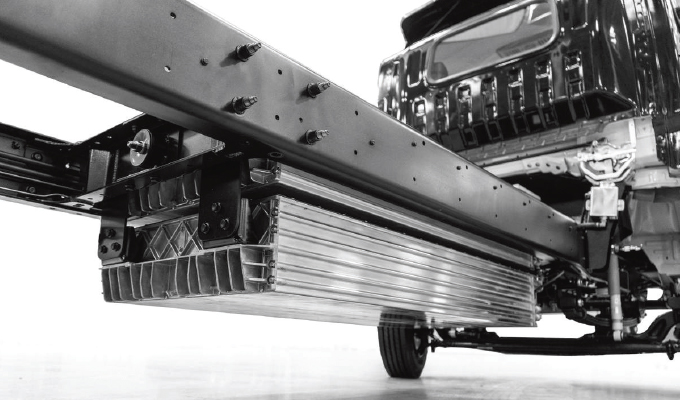

Aside from shear power, the B4 Chassis Cab is built to be durable and efficient. It features a straight beam front axle and a solid rear axle e-drive for higher payload demand. The chassis cab also features a dual wheel drive rear axle. All its rails are flat and straight. The EV’s stackable battery packs fit snuggly between the frame rails for protection and less complexity.

The Class 4-6 B4 Chassis Cabs feature GVWR from 15,000 to 22,000 lbs. The vehicles can accommodate payloads between 7,080 and 13,300 lbs. Choose between multiple wheelbases with all three classes, from 158 inches to 208 inches, whichever better fits the necessary body type for the application. And speaking of the best fit, the B4 Chassis Cab is designed to accommodate different body types, such as a box truck, bucket truck, or more.

SAFETY

No matter which Bollinger Motors vehicle a fleet owner chooses, rest assured, fleet drivers will be safe. That’s because for Bollinger Motors, safety is paramount. A backup camera and a backup alarm come standard with the B4 Chassis Cab. Additionally, all components rest inside the steel frame rails. This is a safety benefit, but it also allows for easier upfitting.

EV SAVINGS

The Bollinger Motors Chass-E redesign resulted in a vehicle designed from the ground up with an emphasis on efficiency and safety. The brand designed the trucks to make the switch to electric seamless for existing fleets.

Not only was the truck designed to benefit fleet owners, its manufacture and assembly will benefit fleet owners, as well. This is because Bollinger Motors designs, engineers, and assembles its vehicles in the USA, locally sourcing as many materials and components as possible. This keeps the Bollinger Motors overall cost of operation lower—a savings that Bollinger Motors passes along to its customers.

In addition to operational savings, the total cost of ownership for an electric fleet truck is projected to be thousands of dollars lower than the total cost of ownership for vehicles with an internal combustion engine. Bollinger Motors estimates its B4 Chassis Cab’s total cost over 10 years to be around $190,000 compared to a similar diesel chassis cab, which Bollinger Motors estimates a 10 year total cost around $280,000—and this excludes savings and rebate from government incentives.

With Bollinger Motors’ goal of making the switch to EVs seamless and with the lower total cost of ownership, all that’s left to do is decide what configuration is best for your fleet.

FOR MORE INFORMATION

Find out more about the Bollinger Motors B4 Chassis Cab, visit www.bollingermotors.com.