From October 2019 to January 2020, VMAC, manufacturer of vehicle-mounted air compressors, surveyed 205 individuals. These individuals come from a variety of industries such as construction, equipment repair, oil and gas, mining, and agriculture. Although those surveyed are from various industries, they each have one thing in common: They use mobile air compressors in their daily operations.

The goal of the survey was to allow mobile air compressor users to compare their operations and usage to other businesses also using mobile air compressors. The results show a number of industry trends including the number of trucks in a fleet, type of vehicles used, most important equipment on the vehicle, and much more. Read the results to see how your answers compare with your peers in the industry. Perhaps viewing industry trends will influence business decisions in the future.

job title

SELECT THE JOB TITLE/FUNCTION THAT BEST DESCRIBES YOU

VMAC’s survey began with getting to know the respondent. The survey found that 32% of respondents were owners—usually the decision-makers of the company—while 23% of respondents were operators or mechanics. The other 45% of respondents comprised of fleet managers, sales/marketing, upfitters, and others.

industries served

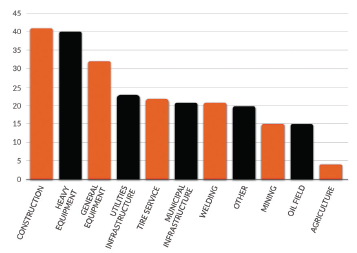

WHAT INDUSTRY DO YOU SERVE? CHECK ALL THAT APPLY

Respondents were asked to identify the industries they served, checking all that apply. Construction and heavy equipment dominated the industries served with general equipment, utilities, and tire service following behind.

size of fleet

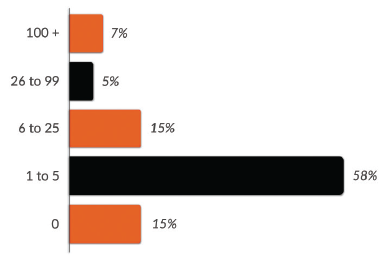

HOW MANY SERVICE TRUCKS ARE IN YOUR COMPANY’S FLEET?

The survey indicated that most respondents came from small fleets—about 58% of them. Large fleets of 100 vehicles or more made up only 7% of survey respondents.

age of fleet

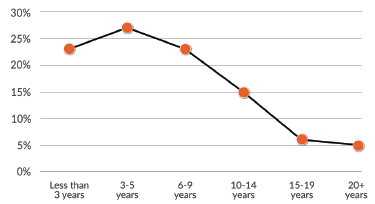

WHAT IS THE AVERAGE AGE OF SERVICE VEHICLES IN YOUR FLEET?

Newer vehicles typically cost less to maintain and feature fuel-saving technology among other perks. Whether these are the reasons many fleet owners keep a young fleet, VMAC’s survey indicates that having a newer fleet is a popular choice with fleet owners. The survey found that 74% of fleets are made up of fleet vehicles that are 0 to 9 years old. Only 5% of respondents reported an average age of 20 years for fleet vehicles.

vehicle class

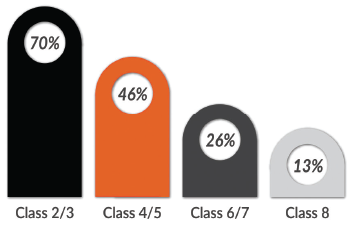

WHICH CLASSES OF SERVICE TRUCKS DO YOU HAVE IN YOUR FLEET?

CHECK ALL THAT APPLY.

As newer vehicles trend among fleets, so do smaller classes of vehicles. Respondents were asked to check all classes of vehicles that apply to their fleet. Class 2 and 3 (70%) and Class 4 and 5 (46%) were the prominent players in this category.

van numbers

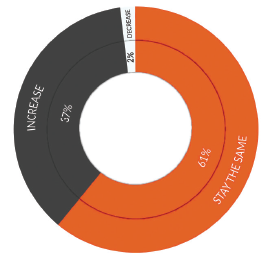

DO YOU ANTICIPATE THE NUMBER OF SERVICE VANS IN YOUR FLEET TO INCREASE, DECREASE, OR STAY THE SAME?

According to the survey, 61% of respondents do not plan to increase the number of vans in their fleet, but they don’t plan to decrease that number, either. However, 37% of respondents would like to increase the number of vans in their fleet, where only 2% plan to decrease.

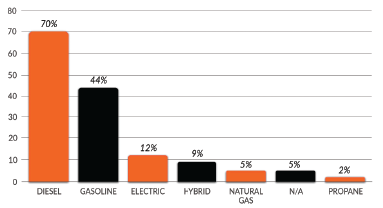

future purchases

WHAT KIND OF SERVICE VEHICLES ARE YOU INTERESTED IN PURCHASING IN THE FUTURE? CHECK ALL THAT APPLY

Respondents were asked what kind of vehicle they are interested in purchasing in the future and to check all that apply. Diesel was the top choice at 70% with gasoline also a top choice at 44%. According to this survey, alternative fuels are not quite on everyone’s radar yet. The highest percentage of those interested in purchasing alt-fueled vehicles is at 12% with electric.

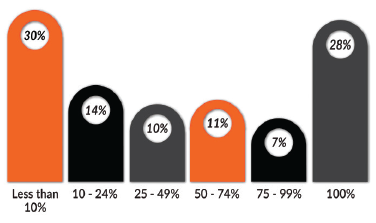

in the fleet

APPROXIMATELY WHAT PERCENT OF YOUR SERVICE VEHICLES ARE EQUIPPED WITH AIR COMPRESSORS?

A divide exists between those whose vehicles are equipped with air compressors and those whose vehicles aren’t equipped with air compressors. While 30% of respondents indicated less than 10% of their vehicles are equipped with an air compressor, 28% indicated that 100% of their vehicles are equipped with them.

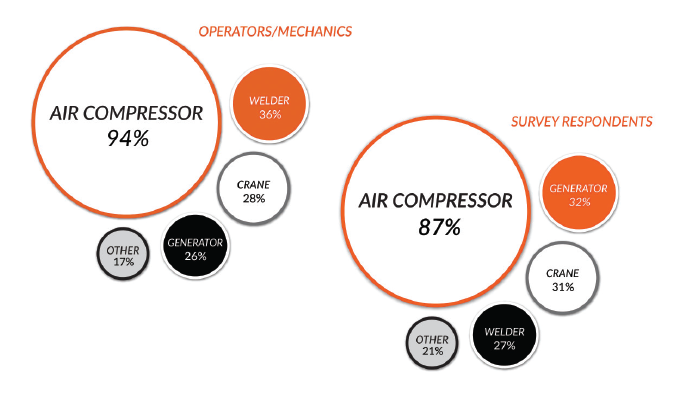

important equipment

WHAT ARE THE TWO MOST IMPORTANT PIECES OF EQUIPMENT

ON YOUR SERVICE VEHICLE?

Respondents were asked to indicate which two pieces of equipment on their service vehicle were the most important. Of the options, 87% of respondents indicated that their air compressor was one of their top two most important pieces of equipment.

When the answers were segmented by job title, the Operator/Mechanic’s group indicated that 94% chose an air compressor as a top two most important piece of equipment. Welder was the next in line at 36%.

compressed air importance

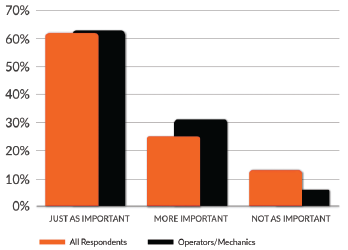

HOW IMPORTANT IS COMPRESSED AIR IN RELATION TO OTHER EQUIPMENT FITTED ON THE SERVICE VEHICLES?

How important is compressed air compared to other equipment on a service vehicle? A majority of respondents (87%) believe it is just as important or more important. But when answers were segmented by job title, 96% of Operators/Mechanics indicated that compressed air is just as or more important than other vehicle-mounted equipment.

cfm/psi requirements

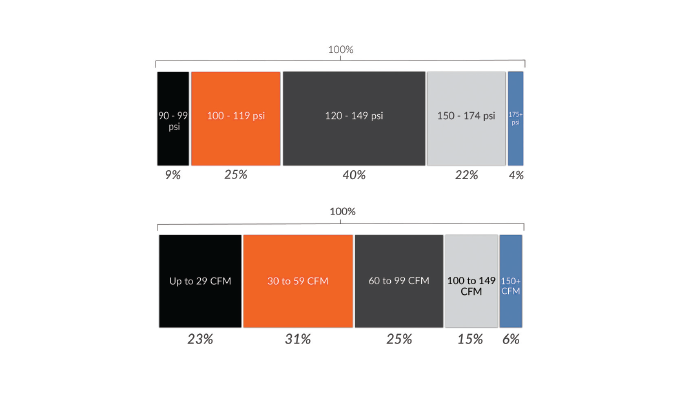

WHAT CFM RANGE BEST FITS YOUR REQUIREMENT FOR SERVICE VEHICLES?

Over half of VMAC’s survey respondents require up to 59 CFM on service vehicles (54%). Those who require 60 to 149 CFM make up 40% of respondents. Only 6% require more CFM.

Most respondents indicated a need of 100 psi or more (91%).

common air tools

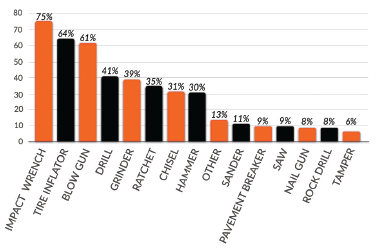

WHAT ARE THE MOST COMMON AIR TOOLS YOUR SERVICE VEHICLES USES? CHECK ALL THAT APPLY.

Survey respondents selected the most common air tools they use in their operations. The majority use an impact wrench (75%), tire inflator (64%), and a blow gun (61%).

rotary vs reciprocating

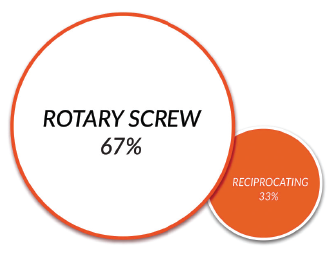

DO YOU PREFER ROTARY SCREW OR RECIPROCATING AIR COMPRESSORS

FOR SERVICE VEHICLES?

Do you prefer rotary screw or reciprocating air compressors? The majority of VMAC’s respondents prefer a rotary screw (67%) where 33% prefer a reciprocating air compressor.

why rotary screw?

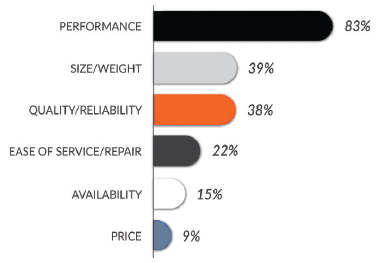

WHY DO YOU PREFER ROTARY SCREW AIR COMPRESSORS FOR SERVICE VEHICLES? CHECK ALL THAT APPLY.

When asked why they prefer a rotary screw air compressor, the majority noted it was because of their performance.

why reciprocating?

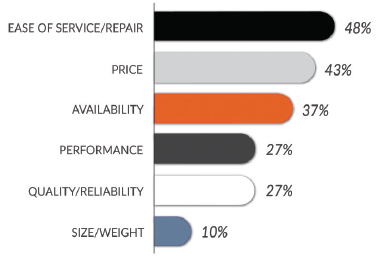

WHY DO YOU PREFER RECIPROCATING AIR COMPRESSORS FOR SERVICE VEHICLES? CHECK ALL THAT apply.

When asked why they prefer reciprocating air compressors, almost half indicated it was because of their ease of repair/service.

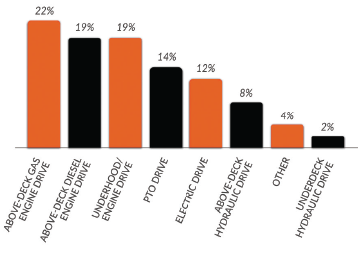

power methods

HOW DO YOU PREFER TO POWER YOUR SERVICE VEHICLES’ AIR COMPRESSORS?

There are various ways to power an air compressor. Above-deck gas engine drive is the option for 22% of VMAC’s respondents. Above-deck diesel and UNDERHOOD™/engine drive took 19% of the vote.

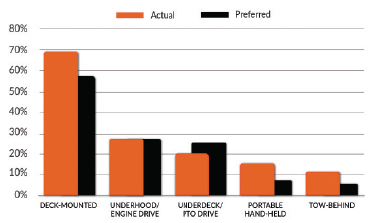

style preference

WHAT STYLE OF AIR COMPRESSOR DO YOU PREFER ON SERVICE VEHICLES? CHECK ALL THAT APPLY.

Respondents were asked which style of air compressor they currently use and which do they prefer, checking all that apply. Deck-mounted air compressors proved to be the most used (69%) and most preferred among respondents (58%).

FOR MORE INFORMATION

The data from this piece was provided by VMAC. Find out more, visit www.vmacair.com/survey.