Why use an idle reduction system? To save your fleet money—it’s that simple, because over time a good system will pay for itself. Of course, how much you pay for the system and how much it reduces your idle time will determine how long that payback period will be.

Idle reduction systems have been around for years and every time fuel prices rise, the interest in these solutions swings into high gear. This increase in interest also drives features and innovation as system manufacturers compete in the marketplace.

As we all know, reducing idle time saves fuel, reduces engine wear, and decreases the need for more frequent LOF (lube, oil, and filter) services—all of which saves a fleet money from their operating budget. And, for those of us operating in states with a strong focus on emissions reduction, not idling means fewer greenhouse gases, making for a healthier environment.

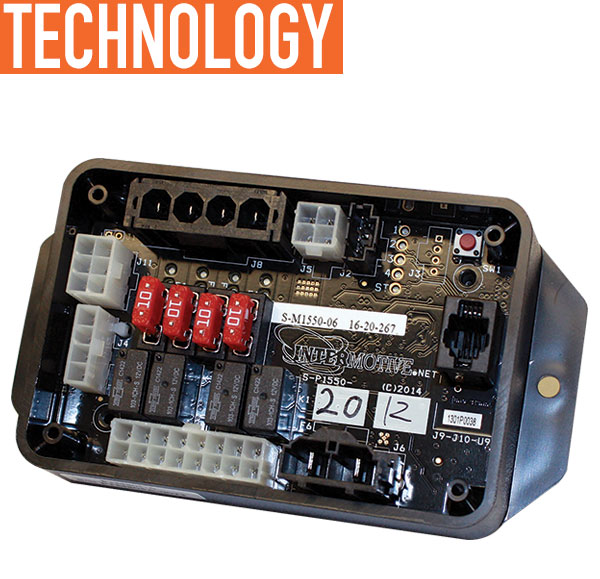

Featured Image: InterMotive module that mounts under the lower dash panel of the truck.

Featured Image: InterMotive module that mounts under the lower dash panel of the truck.

Let’s take a moment to cover the key numbers around the argument for idle reduction as taken from sources including research by Ford Motor Company, www.energy.gov, and US Energy Information Administration: 0.6, 10, 19, 22, and 33.

- The average vehicle uses 0.6 gallons of gas for every hour of idle time.

- A warm engine uses more fuel when it idles for 10 seconds versus restarting.

- Each gallon of gas produces 19 lbs of carbon dioxide (CO2).

- Each gallon of diesel produces 22 lbs of CO2.

- Every hour of idle time is equivalent to driving 33 miles.

When you simply determine how much your average vehicle idles per day, you can calculate the financial and environmental impact idling has on your fleet. Many of you already know your numbers. If you don’t, take a moment to run them after reading this article.

WHAT TO LOOK FOR

With all the options on the market today, you need to map out what features are important to your situation to find the best solution. Ask yourself these questions and rate which ones, if not all of them, are critical to your fleet:

- Do you want a system that is automatic or requires the driver to take some action to operate the system? There are pros and cons to each.

- Shutdown and restart criteria: Do you want a system that stops/starts on battery voltage status, or is it important to stop/start based on temperature inside the vehicle? What about extreme ambient temperature or equipment sensitivity?

- Does the system require the key to be left in the ignition—risking vehicle theft—or does it allow a key out option? Systems that function with the key out of the ignition double as a theft deterrent system by preventing an unauthorized user from shifting out of Park without the key.

- How important is the ease of installation and removing the system when the vehicle is decommissioned? Plug and Play (PnP) connections to the chassis may mean a higher acquisition cost but a lower installation labor time. In addition to the cost implication, PnP solutions mean no cutting of factory wires and a more reliable installation. A challenge for many systems is that some connectors (e.g., ignition connectors) are not commercially available. Some manufacturers overcome these issues by designing their own connectors which are not available in the marketplace.

- Can the settings of the system be customized to your specific needs and how easy is it to change the settings, should your needs change? Look for a system that allows simple programming with a cable or Bluetooth technology using a mobile app. With growing concerns over cyber security by vehicle manufacturers, a system that requires a direct cable or Bluetooth means anyone attempting to connect is within feet of your vehicle and not halfway around the world.

WHAT ABOUT THE DATA?

Of course, none of the information above is meaningful unless you can access your data in a format that is easy to use. The use of Bluetooth technology and a mobile app is an efficient way to collect idle reduction data quickly, in a clean format, and show how the calculations were made. Obviously, this technology lends itself to a fleet using smartphones and tablets already in service and not having to acquire more equipment and adding to the cost of their system.

Information your data report should provide:

- How much time did the vehicle idle?

- How much time would the vehicle have idled if the system had not been active?

- How much did you save on fuel, emissions, and most importantly, cost?

Does the report allow you to change data factors such as fuel costs or gallons per hour of idle, should your results be different than the default standards? This may sound basic, but don’t overlook this point: Will you own your fleet’s data, or will it be owned by the company that provides you the idle reduction system?

There are solutions available for every need and every budget. Don’t pay for more than what you need, but don’t settle for less either. The goal of this article is to offer thoughts on what should be considered when looking to purchase an idle reduction system, not to tell you what is right for your fleet.

FOR MORE INFORMATION

Marc Ellison is a director at InterMotive and has more than 30 years of experience in the automotive industry, including 17 years at Ford Motor Company. To learn more about idle reduction technologies, what features you need to look for, or where to acquire InterMotive’s products, visit www.intermotive.net.

_______________________________________________________________________

MODERN WORKTRUCK SOLUTIONS: FEBRUARY 2018 ISSUE

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern WorkTruck Solutions magazine.

![]()