Retreading has been around since the beginning of the 1900s, and during WWII, synthetic rubber was invented due to the import restrictions of natural rubber. Since the development of synthetic rubber was in its infancy, it did not perform as well as anticipated, and memories of this still plague the industry.

Retreading has advanced by leaps and bounds since its beginning, not unlike other technologies. I like to use several analogies when comparing the old technology of retreading to today’s advanced retread process and the advancements in tread development.

Look at how far vehicles have come since the Model T. Look at fleets and understand that we don’t use the same trucks we did 80 years ago. Consider phones. Are phones the same as they were 50 years ago? I remember my first cell phone weighed 2 lbs and worked about half the time. When it did work, it cost 50 cents a minute. Now we all have smartphones that work 99% of the time with unlimited plans.

MORE MILEAGE

The advanced tread rubber of today runs as good if not better than the original tread, and the actual process that the modern-day retreader uses to inspect, prepare, apply, and vulcanize the tread rubber to the casing has advanced as well. Therefore, if you do not already incorporate retreading into your tire program, I suggest you start.

In 2022, the US truck tire replacement market came in at 42 million, of which 16 million were retreads.

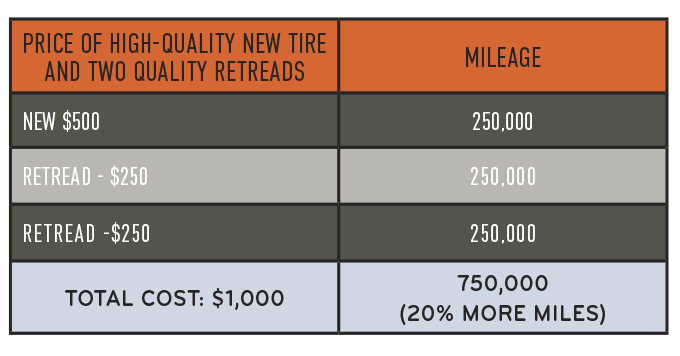

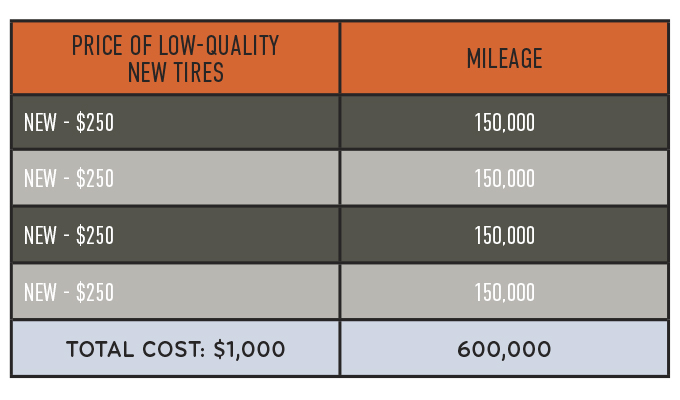

A quality new tire with two retreads can deliver approximately 20% more miles than four new one-and-done low-quality, low-cost tires that have to be thrown away once the new tread is worn down. The charts on page 31 only reflect an average cost comparison between the two kinds of tires.

BUSTED MYTHS

We have addressed that today’s retreads are more advanced and superior to days gone by, so now let’s address some of the retread myths you may or may not have heard of before. The below busted myths are from the Tire Retread & Repair Information Bureau (TRIB).

Myth: Rubber on the road comes from retreaded tires.

Fact: The rubber pieces you see on the road come from both new and retreaded tires in equal proportions to their usage on roads. Multiple Federal and State studies have proven that most of the rubber on the road comes from truck tires and is caused mainly by underinflation, overloading, and tire abuse.

Myth: Retreaded tires are not as safe as new tires.

Fact: Retreaded tires are just as safe as new tires. Adjustment percentages of retreaded tires are about the same as new tires. Statistics compiled by the US Department of Transportation show that nearly all tires involved in tire-related accidents are underinflated or bald. Properly maintained tires, whether new or retreaded, do not cause accidents.

Myth: Retreaded tires can’t be driven at highway speeds.

Fact: Yes, retreaded tires can be driven at the same legal speeds as comparable new tires with no loss in safety or comfort.

RETREADS AT WORK

If retreaded tires weren’t safe, they wouldn’t be trusted by numerous fleets. Retreaded tires are used daily and safely by ambulances, fire engines, USPS, school buses, aircraft, UPS, FedEx, and large and small fleets worldwide. What’s more, according to the United States Environmental Protection Agency, Air Force One, the plane of the president of the United States, uses retreaded tires.

Nearly 100% of the world’s airlines will retread their tires multiple times, and 80% of all aviation tires are retreads.

A GREEN SOLUTION

Now let’s talk about retreads as they relate to the environment.

It takes 22 gallons of oil to manufacture one new truck tire. Most of that oil is found in the casing, which is reused in the retread process. As a result, it takes only 7 gallons of oil to produce a quality retread. In fact, according to the US Environmental Protection Agency, retreading is responsible for saving North Americans more than 400 million gallons of oil every year. Therefore, the retreading process produces significantly less carbon emissions than creating a new tire.

All in all, when using state-of-the-art technology, retreading uses only 30% of the energy it takes to produce a new tire.

Additionally, retreading significantly reduces solid waste disposal problems. Over 300 million scrap tires are generated every year. When a tire is retreaded, it doesn’t end up in the landfill, which helps decrease this number.

Further, retreading is economically sound because approximately 70% of the cost of a new tire is in the tire casing. With proper maintenance, retreading permits the continued use of the fleet’s investment. On average, a premium quality new tire tread lasts around 250,000 miles. Still, the casing has an average life of approximately 750,000 to one million miles, so retreading saves money and will nearly always increase mileage. A retreaded tire can cost 50% less than the cost of leading brand-new tires. This translates to millions of dollars in annual savings for consumers and trucking fleets.

The quality of a well-crafted American-made retread tire is far superior to a new, one-and-done low quality, low-cost imported tire, and not to mention, retreading supports thousands of American jobs.

RETREAD FACTS

Retreading uses only 30% of the energy it takes to manufacture a new tire.

A retreaded tire costs 30 to 50% less than a new tire.

Tread rubber manufacturers do not add wire or metal material to the tread. So, the next time you see a road gator on the side of the road, look and see if you can see some wires. If you do, the failure was more than likely caused by under or over-inflation, road hazard, etc.

ABOUT THE AUTHOR

Ron Elliott is the marketing manager for Pre-Q® GALGO and responsible for leading the marketing direction of the long-term growth strategy for the brand throughout the United States and Canada. Elliot previously worked for Marangoni Tread North America as marketing manager and has over 30 years of sales and marketing experience in diverse industries. He was also the spokesperson for Retread Instead for three years as well as a contributor for Retreading Business Magazine. Reach him at relliott@pre-q.com. Find out more about retreads, visit www.retread.org or www.pre-q.com.