Preparing your equipment for the challenges of the season ahead keeps you safe and helps preserve the resilience of your truck equipment. Monroe Truck Equipment’s versatile work-ready trucks, commercial snowplows, and service parts help all season landscapers and contractors offer high-value services every day of the year. Read ahead for some snow season preparation tips to help plan for the winter.

1. CHECK THE OVERALL CONDITION OF YOUR EQUIPMENT

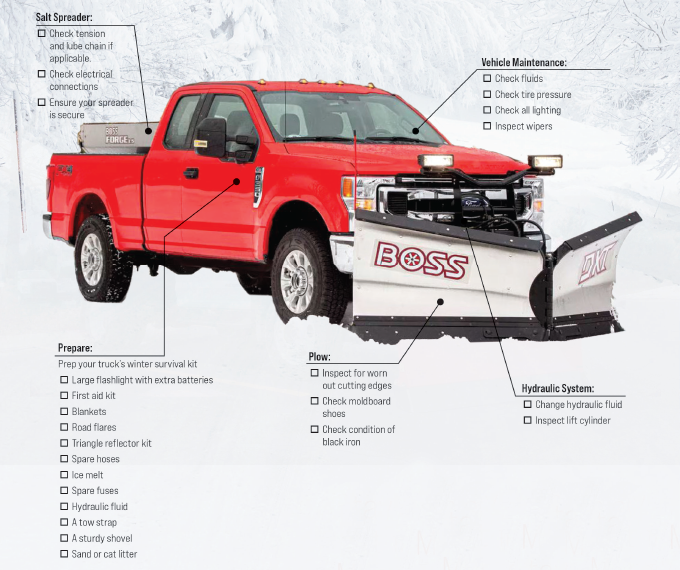

Regular maintenance and daily inspections are vital for maintaining the health of your plow and truck. Keep an eye open for typical damage that occurs during plowing season such as cracks in the framework of your plow, the plow moldboard, trip springs, and the vehicle’s undercarriage.

2. CHANGE YOUR HYDRAULIC FLUID

During the summer season with the hot weather and high humidity, condensation can quickly build up from moisture in the air. Replacing the fluid will ensure your unit is free of water or any debris and help keep your plow operating properly through snow and ice season.

3. CHECK ALL NUTS AND BOLTS FOR TIGHTNESS

There are many fasteners on your plow and vehicle undercarriage. A daily inspection of these fasteners is recommended during plowing season. You should refer to your plow manual for the manufacturer’s recommended torque specifications.

4. TEST YOUR ELECTRICAL SYSTEM

The plowing season can be hard on your vehicle’s charging system. It is always a good idea to do a few pre-season checks. You should always ensure that your battery connections and plow connections are corrosion free and in good condition. It is also a good idea to have your vehicle battery load tested if it has some age to it. It is good practice to coat your electrical connections with a dielectric grease or another type of non-corrosive battery protectant.

5. CHECK YOUR HYDRAULIC COMPONENTS FOR WEAR AND DAMAGE

A good visual inspection of your hydraulic components can save you time and money down the road. Before each use you should look at the packing seals on the lift/angle cylinders for leaking or loose packing. Inspect all hoses for leaks and chaffing. An annual pump pressure check is recommended, but not required. It is always a good idea to carry an additional quart or two of hydraulic fluid for your plow.

6. INSPECT ALL THE LIGHTS

Reduced visibility in a snow storm is incredibly dangerous. Routinely checking all of your lights and replacing wherever necessary will prevent any unnecessary accidents or danger. Additionally, make sure to check your internal lights as well to make sure you’ll be able to easily see and reach any tools you’ll need while on the road.

7. TEST THE SALT SPREADER

Whether your spreader is gas or electric, run a test before you have to spread on the roads. Never store salt or any corrosive material in your spreader for extended periods of time as it can greatly decrease the life of your equipment. Check the drag chain for proper tension, then inspect and grease all bearings and chains.

8. LOOK FOR WORN OUT CUTTING EDGES

All the tightening and checking you’ve done so far will do no good if you have a worn-out cutting edge on your blade. It’s commonly recommended that you replace your plow’s cutting edge when it’s worn down to about four inches.

9. PREP A WINTER SURVIVAL KIT FOR YOUR TRUCK

This kit is something no one hopes to ever use, but it’s imperative that you have quick access to emergency tools. Things to have on hand include:

- A large flashlight with extra batteries

- First Aid kit

- Blankets

- Road flares

- Triangle reflector kit

- Spare hoses

- Ice melt

- Spare fuses

- Hydraulic fluid

- A tow strap

- A sturdy shovel

- Sand or cat litter

Here’s to a safe and prosperous snow and ice season.

FOR MORE INFORMATION

Find out more, visit www.monroetruck.com.