As we progress further into the 21st century, the need for efficient and versatile cargo handling solutions in work van applications becomes increasingly essential. It’s not necessarily about making work easier; it’s about making it smarter and sometimes simpler in the process.

Hydraulic liftgates and compact electric cranes are indeed beneficial for offloading some equipment and cargo types from vans, but these technologies have their own sets of challenges, such as upfront cost, maintenance, service downtime, and training requirements.

According to Vinny Lamontagna, US Upfitters’ sales manager, “In this case, the most straightforward solution is also the least expensive and most versatile—it’s an aluminum ramp—and it will get the job done.”

Small liftgates and cranes don’t just drain vehicle batteries; they also require significantly more maintenance and cost, between two to four times more, to purchase and install than a ramp,” comments Kevin Parker, founder of Advantage Outfitters. “Depending on the specific application and the type of freight or equipment involved, ramps, particularly spring-assist aluminum ramps, are a highly practical and versatile solution catering to a wide range of needs.”

A SWIVEL STANDARD

Over the decades, advancements in design, engineering, and materials have meant advancements in ramp design, and using all three, Link Manufacturing has set the standard.

Link ramps mount just within a vehicle’s doors, occupying less than 12 inches of horizontal space. Unlike hydraulic liftgates, Link ramps require no training to operate, enabling workers to start using them immediately after installation.

Link’s swivel ramps mount in the rear stored position like a traditional folding ramp. The ramps can also be swiveled behind the wheel well, providing unobstructed vehicle access and options for times when a ramp isn’t needed.

Some Link ramp models come with an optional built-in spring-assist feature. With this feature, opening and closing a ramp requires a minimal amount of effort.

Link ramps are designed to meet a variety of uses, with dimensions ranging from 24 to 47 inches in width, comfortably accommodating standard hand trucks and other cargo conveyance equipment. Bifold ramp lengths vary from 72 to 135 inches, while extended ramp models can reach 119 inches, featuring an adjustable support mechanism for added stability.

In 2021, Link introduced a 42-inch by 108-inch ramp to its line of nine standard ramp designs, catering to an array of applications. This new addition provides more ramp width without obstructing door access when mounted to one side and folded into its upright, storage position.

“Link ramps often outlast more than one vehicle; we just remove them and put them in a new van,” Lamontagna says. “They make our customers happy—and that’s why we always keep them in stock.”

LIGHTENING THE LOAD

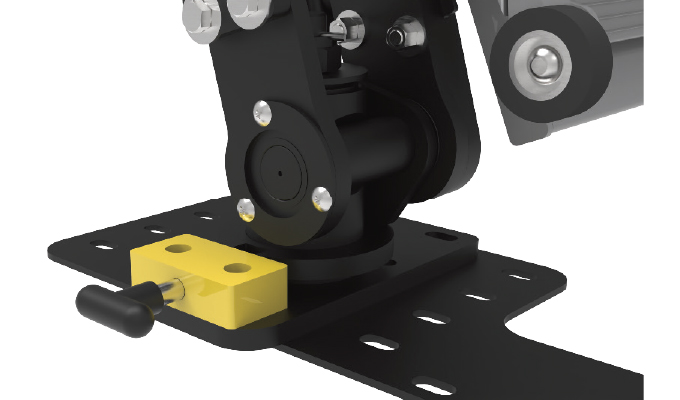

Link recently modified its product line, focusing on weight reduction and improved mounting solutions for its aluminum swivel ramps as well as improved bumper clearance for its entire ramp line. This evolution allows for even greater flexibility and adaptability for those in the fast-paced world of work van upfitting.

“We were excited to hear that Link had made its remarkably good product line even better,” Lamontagna adds. “Their new swivel and folding ramp designs will help make our installation process easier and our customers happier.”

The company’s light-weighting effort led to approximately 30 lbs shed from the ramp’s original mounting plate design. Link achieved this impressive weight reduction through optimization of the ramp’s base plate geometry, reducing material where it wasn’t necessary, such as between connection points on the left and right.

“The goal was to maintain the robustness and structural integrity of our swivel ramps while making them easier to install and handle,” explains Nick VanderKooi, Link Manufacturing advanced engineer. “Our new design also features a more flexible generic grid pattern for mounting fasteners, giving our customers greater versatility in deciding where they mount the ramps.”

This led to significant improvements in the ease of installation. Link’s installation instructions are now much more straightforward. This, combined with the addition of extra mounting holes, makes it easier and faster for upfitters to install Link’s swivel ramps.

So, what does a 30-lb weight reduction mean in real-world applications? Link’s swivel ramps now weigh between 157 and 225 lbs, translating to a weight savings of 13.3 to 19.1%, depending on the ramp model. This lighter-weight mounting plate is also easier for upfitters to install and provides benefits to end users, such as improved fuel efficiency and less stress on the vehicle structure.

ELEVATING EFFICIENCY

Link Manufacturing is also working on a design modification that improves the functionality of not only its swivel-ramp design, but its folding ramps as well. A new extended spring design configuration allows both types of Link ramps to better clear their host vehicle’s bumpers.

“So on all ramps of 108 inches and longer, we moved our spring-assist components farther down the ramp,” VanderKooi says. “That way we can get additional clearance above the vehicle’s bumper, giving upfitters a little more flexibility in the mounting location. Now they can mount the folding ramp farther into the vehicle if they need to, and it gives them a lot more clearance to the bumper.”

The innovative clearance feature targets the step van market because that’s where users most often see interference with ramp-to-bumper contact. On Link’s swivel ramps the new design provides about 3 to 4 inches of increased clearance above the bumper. On Link’s LB20 model folding ramp, the new design accounts for 8 or 9 inches of increased clearance.

“The versatility and practicality of ramps, particularly spring-assist aluminum ramps, meet a wide variety of our needs,” says Advantage Outfitters’ Parker. “And with Link’s constant innovations, they continue to be an extremely practical and versatile solution.”

FOR MORE INFORMATION

Find out more about Link ramp products, visit www.linkramps.com.