By Alastair Hayfield

As the song goes, “Birds do it, bees do it; even educated fleas do it. Let’s do it, let’s fall in love.” And so engine manufacturers seem to be rushing to fall in love with hydrogen combustion engines. JCB announced in May that it would develop such a solution. And hot on the heels of this news Cummins, Caterpillar, Liebherr, and the GAC Group made announcements that they will also develop hydrogen combustion engines for a variety of applications. Is it a mad rush of blood to the head, or is it a sensible strategy for commercial vehicles?

IN THE BEGINNING

Hydrogen was the first element to form from the cooling maelstrom of the Big Bang. It is the most abundant element and, in some ways, the most abundantly talked about when it comes to decarbonization. In various quarters it is viewed as a panacea: It will help curb global warming while allowing society to maintain the dual privileges of personal transport and high-energy use. It can be produced sustainably from renewables (wind or solar) and, when it is used in a fuel cell system, produces zero emissions, save water. In the mix of combustion engines fueled by hydrocarbons, hybrids, battery electrics, and hydrogen fuel cells, is there room for another engine type?

THE COST

A hydrogen-fueled combustion engine works in much the same way as a diesel-fueled combustion engine. Hydrogen is combusted to produce water with no carbon-based emissions; however, the temperature of the reaction produces nitrogen oxides, which are harmful to human health. While these emissions can be minimized by controlling the combustion process or aftertreatments, they can never be completely removed, and the control process adds costs to the engine.

In addition to emissions and the costs associated with minimizing them, a “regular” combustion engine designed to use diesel must be modified to run on hydrogen—adding further cost. Additionally, a weighty set of high-pressure hydrogen tanks must be added to the vehicle, further increasing cost and decreasing the cargo payload.

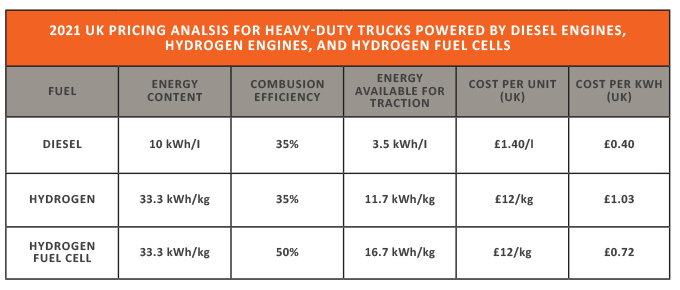

But surely there is some payback on fuel costs even if the engine costs more? If we assume that the system efficiency of diesel engines and hydrogen engines is the same and that the engines have the same power output, we can look at the table at the bottom of the page based on UK pricing.

DOES IT MAKE SENSE

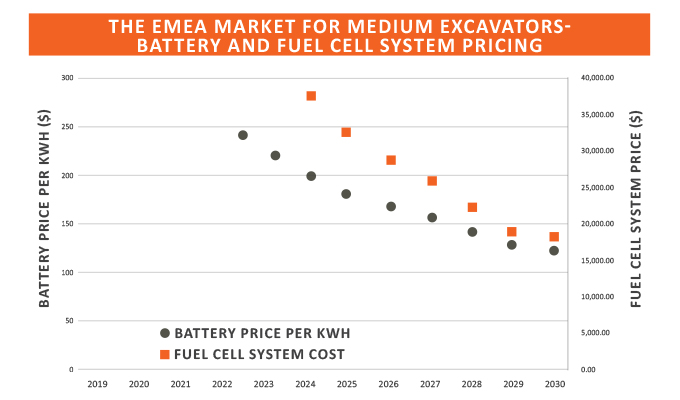

The current cost of hydrogen means that not only is the engine/vehicle more expensive, but it costs more to run. Proponents of the technology will argue that the cost of hydrogen will decrease with scale (true, but likely on a timeline of five to 10 years) and that “electrified” powertrains—battery or fuel cell—cost more upfront. On this latter point, that is currently true. But our research at Interact Analysis shows that both the battery and the fuel cell system are and will continue falling in price over the next five to 10 years. Not only will this bring the purchase price of an electrified powertrain closer to parity with a conventional engine powertrain, but with lower running costs associated with electricity, the total cost of ownership will be lower—at least for battery electric systems (see table on page 26).

Then, there is the issue of where hydrogen comes from. While hydrogen is “clean” locally (meaning, when an engine or fuel cell consumes it), it is “dirty” when it is produced, with the majority coming as a byproduct of the fossil fuel industry (brown hydrogen). It is possible to produce green hydrogen (hydrogen produced by the electrolysis of water where the whole process is powered by renewable electricity), but this is considerably more expensive than brown hydrogen. Therefore, is it practical to combust it in an engine compared with using it much more efficiently in a fuel cell?

Given all of the above, why are certain manufacturers even considering this solution? It’s because hydrogen combustion engines represent an alternative. It makes use of an existing technology: It is “here and now,” and it doesn’t produce carbon dioxide. The nitrogen oxide emissions are problematic, but regulators may allow some leeway if emissions can be minimized or if they are limited to certain remote locations.

MORE QUESTIONS

Across passenger cars, trucks, buses, and even off-highway vehicles, manufacturers realize that they need to decarbonize with some urgency. However, this realization comes with a cost: huge investment in new powertrain technologies, vehicles, and processes. While larger manufacturers may be able to stomach this cost, others without deep pockets or significant exposure to investments in internal combustion engines may be looking for ways to make best use of the products that they already have.

It’s clear that hydrogen combustion engines make use of the traditional engine technology stack and supply chain and easily slot into the service and maintenance offer of most manufacturers. This makes their use appealing, particularly as they can help reduce carbon emissions while preserving investment, jobs, and supply chains. But there is a risk that this is short-sighted. Will governments or cities crack down on NOx emissions rendering the technology useless? Will investments and time spent developing hydrogen combustion delay focus on the electrification technologies? And is it just moving the pollution problem from “local” to “elsewhere”?

Another factor in pursing hydrogen combustion engines is the idea that it will drive more demand for hydrogen, bringing down the cost of production. If more vehicles are in operation that need hydrogen, there will be greater incentive for producers of hydrogen to scale production and reduce costs, bringing the price of the fuel down. This will help support the use of not only hydrogen combustion engines, but also hydrogen fuel cells and a broader hydrogen economy. The work by JCB and Liebherr, for example, when viewed in the context of the hydrogen economy in the UK and Germany could make a lot of sense. An increase in hydrogen machines—combustion or fuel cell—could be all the impetus that is needed to kick-start a hydrogen economy.

WHAT’S THE GOAL

Are hydrogen combustion engines a smart solution to the problems of decarbonizing heavy-duty machinery or a pointless dead end that is dressed up to play well at the 2021 United Nations Climate Change Conference (COP26)? It is a question with a messy answer: It all depends on your goal.

If you are trying to decarbonize a heavily energy intensive application, cost considerations would make a hydrogen combustion engine a practical solution for end-users versus trying to persuade them to buy a battery electric or hydrogen fuel cell model. If your company is deeply invested in internal combustion solutions and has a finite R&D budget—or is reliant on an internal combustion-based supply chain—it makes sense to develop a hydrogen combustion engine as a path to decarbonization. If your business is operating in markets where an adoption of hydrogen machinery will help drive the costs of hydrogen fuel down, then it probably makes sense to pursue hydrogen combustion.

CONSIDERABLE FACTORS

So, for JCB and others, there is rationality to the decision; however, does that make it the right decision overall? There are several risks at play here. First, the cost of hydrogen is currently much higher than that of diesel or electricity. This factor will be a key consideration of end-user adoption. If there is no clear push to use the solution to decarbonize from legislators, then end-users are not going to pay more for the machine and the fuel. Second, if regulators decide to heavily penalize or ban NOx emissions, then this technology is not a practical solution. And recent announcements from COP26 put several major countries on a path to do just that. Third, this is likely the best fit for very intensive applications in construction or agriculture. However, many of those sites are a far from central locations, particularly transit corridors, and this makes the distribution of hydrogen and the storage of it onsite complex and expensive.

At Interact Analysis, our research shows that, while the technology clearly has the potential to reduce carbon emissions, the use of hydrogen combustion engines in heavy-duty applications will be limited because of the challenges with machine and fuel price, the small number of suitable applications, and the shift toward battery and fuel cell solutions in many other applications.

ABOUT THE AUTHOR

Alastair Hayfield has over 15 years’ experience leading research activities in scaled, high-growth industrial and technology markets. As senior research director of Interact Analysis’ Commercial Vehicles Division, he is responsible for research on electric trucks and buses, autonomous trucks, and off-highway electrification. Find out more, visit www.interactanalysis.com.