By Jeff Hunter

Construction schedule setbacks can appear to be an intractable problem, increasing each project’s uncertainty, risk, and waste. According to McKinsey and Company’s “Imagining Construction’s Digital Future,” large capital projects are typically 20 months behind. Delivering materials that aren’t in specification is a major culprit in hampering jobs from on-time completion. Depending on the situation, it can also cost the ready mix producer a lot of money.

Concrete’s consistency changes with time due to the amount of water, type of aggregates, evaporation of the mix, ambient conditions, admixtures, the time it takes to deliver, and more. The more manual processes thrown into the mix while in transit, the more your materials are prone to error. There’s a plethora of things that can go wrong when trying to obtain the proper specification while in transit to the job. You add too much water, you don’t add enough water, or the mixture is at the wrong temperature.

The need to pull up poured concrete of poor or questionable quality costs a lot of money—and addressing inconsistency in delivered material results in wasted time and money. Supply chain visibility is the key to making sure your concrete is correct when it arrives at the jobsite.

CALCULATING COSTS

A “cost of doing business” that producers accept is the overdesign of the strength of mix designs to ensure the quality of the final delivered product. After all, living with the money spent on materials needed for overdesigns is better than the impact of delivering concrete that either gets rejected or gets placed and then must be removed.

Industry averages on the overdesign of concrete is about 30% to 36% with about 20% being necessary to ensure test results meet specified amounts. For an annual production of 500,000 cu yds and an estimate of 5% overdesign, the cement costs on excess overdesign would equal $620,000 annually.

Furthermore, there are multiple critical parameters for quality control testing of ready mix concrete, which require taking a sample of the fresh mix to test:

- Workability: Ensuring batch consistency is correct in terms of slump or spread

- Temperature: Ensuring the concrete is delivered within standard or job-specific limits

- Unit Weight, Yield, Air Content: To ensure correct volumes are delivered and the desired air content is achieved

Often producers will spend time in the yard or at the jobsite testing and adjusting the slump. If producers had visibility into the concrete properties while a load is in transit, they could ensure the proper quality of the concrete without wasting time to make adjustments.

The average cost estimate of one minute of delivery time is $1.27 with the average time to adjust the slump equating to 5 to 15 minutes in every delivery cycle. A single truck delivers about 600 loads per year, so the cost to adjust the load based on five-minute delays equates to around $3,800 per truck annually. If you have 100 trucks, that is $380,000 dollars spent per year for a fleet to make load adjustments at the jobsite.

Producers don’t realize that the cumulative results of the money spent on these small buckets of time and material over-usages has a significant impact on their bottom line.

KNOW YOUR CONCRETE

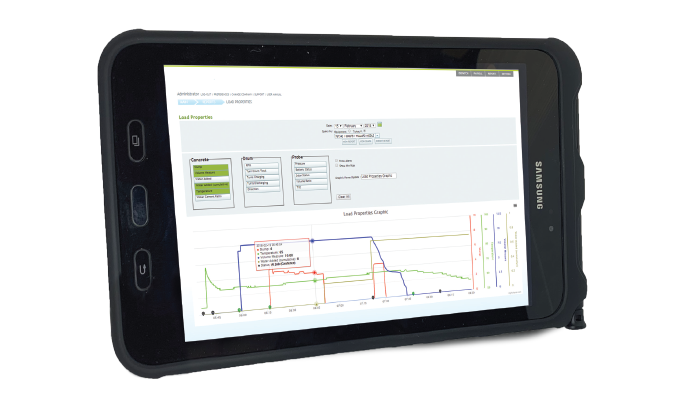

Solutions are available to ensure quality concrete from batch to pour. Concrete telematics solutions help ready mix producers gain visibility in real time into the fresh concrete while in transit. A stainless-steel probe goes into the drum of the truck and integrates the data collected into other systems for production to dispatch to quality control. Having this data assures quality and job specification requirements are met, while also providing significant safety improvement, material waste removal, and time-saving opportunities.

The stainless-steel probe can measure:

- Current concrete slump and temperature

- Volume in the drum

- Water-to-cement ratio based on additional water added when using a meter on truck

- Water allowed to be added based on water-to-cement ratio and volume of concrete remaining in the drum

- Number of revolutions

- Whether the concrete has reached a homogeneous state (fully mixed)

- Drum RPM

- Drum direction and unload rate

The ability to feed the data back to production enables producers to evaluate and optimize mix designs by reducing standard deviations therefore reducing the need for overdesign of mixes. The data can help with disputes to prove quality of the mix, and producers have proof that the concrete delivered was at the optimal quality for the job. The risk of replacing the concrete already poured can be reduced using the historical information and quality data.

COMMAND SOLUTIONS

Command Alkon’s concrete telematics solution, COMMANDassurance, more than pays for itself by removing the costs of unnecessary truck time in yard and at the jobsite, mix overdesign, and material waste. All while demonstrating how your truck delivers the material ordered in spec, saving contractors and producers time on the job.

The data that the system unlocks helps members across the construction supply chain overcome the leading causes of project delays, boost visibility, and keep jobs on schedule so they can quickly react to issues and remain far ahead of jobsite problems. Tools that provide better supply chain visibility and aid construction project coordination—including a central repository to keep tabs on all construction documents—are a great way to keep teams on schedule. No more finishing projects 20 months after the original timeline; get to know your concrete and bring jobs in on time and in budget.

ABOUT THE AUTHOR

Jeff Hunter serves as vice president at Command Alkon, working directly with COMMANDassurance, Command Alkon’s concrete telematics system. Jeff has over 40 years of experience within the construction and construction materials industries. Prior to his time at Command Alkon, Jeff played many roles in the construction business from laborer to president of a commercial and industrial electrical construction and general contracting firm. Find out more, visit www.commandalkon.com.