You already know that the right vehicle specifications can make a big impact on your business’ bottom line. Decisions you make about vehicle payload, tires, the right transmission for your duty cycle, and a number of other factors can make noticeable differences for your drivers, mechanics, and accountants. But choosing the right engine for maximum reliability, durability, and total cost of ownership can be just as challenging as it is important. Here is a breakdown of what to look for and how to weigh the different factors.

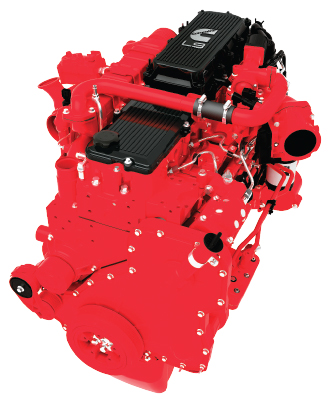

- A PROVEN PLATFORM. Work trucks are essential business tools that are put to the test every day in some of the most rigorous duty cycles. So, you should look for an engine that has withstood the test of time and proven both reliable and durable. The Cummins L9, for example, has successfully used the same basic block and major engine components for over two decades. Have there been upgrades? Absolutely. But the changes have been evolutionary, not revolutionary, in keeping with a policy of continuous improvement.

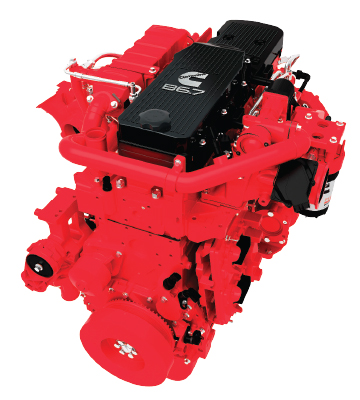

Cummins B6.7

- TOTAL COST OF OWNERSHIP (TCO).

There are a number of factors that impact keeping your TCO as low as possible. Fuel efficiency is a key consideration, especially if you put more than 30,000 miles per year on a vehicle. Maintenance costs can add up significantly based on not just parts and labor but also the opportunity cost of downtime when a vehicle is out of service. Look closely and compare maintenance intervals up front. There have been tremendous advancements in filter technology in the last few years, doubling some intervals and eliminating others entirely. Features such as replaceable wet cylinder liners make it much easier and less costly to perform an overhaul. The final factor in determining TCO is the added value that an engine brings at resale. While no one can guarantee what will happen in the future, there is extensive historical data that strongly suggests that purchasing the most popular and trusted brand will result in a higher selling price when replacing a piece of equipment.

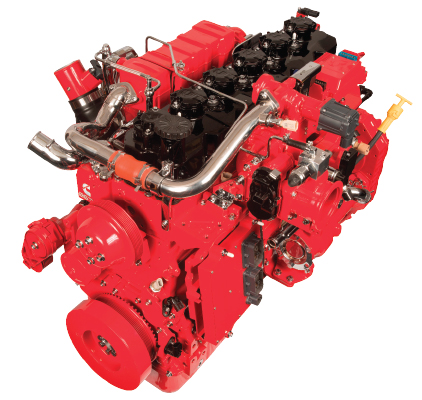

Cummins B6.7N - PTO CAPABILITIES.

Many work trucks, particularly those in vocational applications, require robust Power Take-Off capabilities. Having both rear-engine and front-engine options provides the flexibility you need so you can have a single source for engines while powering different types of trucks within a specialty fleet. - ROBUST EMISSION CONTROLS.

Selective Catalytic Reduction (SCR) and the Diesel Particulate Filter (DPF) were critical elements in meeting the 2017 EPA NOx guidelines as well as the requirement for reduced Greenhouse Gas (GHG) emissions. Diesel Oxidation Catalysts use precious metals, so you don’t want them to get fouled.

Cummins L9 - SUPPORT SYSTEM.

Sooner or later, even the most precise machinery like a Swiss watch needs adjustment. The same holds true for diesel and natural gas engines. When you think about what kind of powerplant to put in a new piece of equipment, make sure you look closely at the service and support capabilities of the manufacturer. Do they employ the same basic technology across product platforms, simplifying maintenance and service procedures? Can you get fault codes transmitted from a worksite to a repair facility or your dispatcher? How large is the services and support network of the engine manufacturer? These are questions you must ask before making a decision.

Cummins L9N - SPEC’ING HELP.

It’s not enough just to choose the right manufacturer and the right engine to match your horsepower and torque needs. You need to get it configured just right to match your transmission and tire size, set the parameters to meet performance objectives and driver preferences, and enable the right feature set. Something as simple as setting the idle shutdown time correctly can make a huge difference in fuel usage. You want to make sure that your local OEM truck provider is taking full advantage of the resources available through the engine manufacturer. If you are buying a Cummins engine, for example, your local distributor or dealer will use a program called PowerSpec™ to help you get everything set up right from the start. Not having the correct spec for your duty cycle can be a costly mistake that you will want to avoid.

If you create a matrix with these six factors and decide which of the factors should be weighted most heavily for your business objectives, it will make doing your due diligence much easier. The result will pay off in the form of efficiency, productivity, reliability, and dependability for years to come.

FOR MORE INFORMATION

Cummins Inc. is a global technology company designing, manufacturing, distributing, and servicing a broad portfolio of reliable, clean power solutions including diesel, natural gas, hybrid, electric, and other alternative solutions. Established in 1919 and headquartered in Columbus, Indiana, Cummins serves customers in more than 190 countries and territories around the world. Find out more, visit www.cummins.com/alwayson.