Winter Equipment offers a complete lineup of gravel road maintenance products to help keep roads even, safe, and maintained after harsh winters. The road grading equipment includes carbide-tipped milling tools, grader blades, scarifier boards, and scarifier teeth.

Designed to reduce replacement costs and downtime, Winter Equipment’s carbide-tipped milling tools deliver up to 300% longer tool life. This is due to a design that reduces the need for replacement because of breakage and uneven wear. Options range from large, high penetration-designed carbide tips ideal for hard rock and gravel conditions and specialty milling tools for low horsepower milling in asphalt (commonly used for pothole patching) to economy, multipurpose milling tools in stationary and freely spinning versions. These milling tools increase production by wearing evenly and maintaining their shape and sharpness, reducing vibration and wear on machinery.

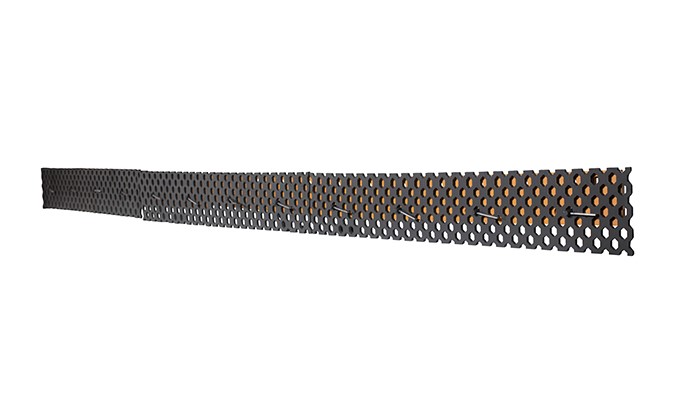

Winter’s perforated grader blades provide operators with quick, easy gravel road maintenance. Additionally, the innovative design helps operators grade gravel roads with ease, breaking up hardpack on top of soil. Winter’s BladeRunner is a blunt underbody cutting edge that offers excellent performance and wear life. BladeRunner removes snow from gravel roads without disrupting the aggregate below.

SCARIFIER BOARDS

Three styles of scarifier boards are available from Winter Equipment. One is engineered for motor graders with 1 to 1.5-inch tool spacing for fine grading, a second with a beveled design for any underbody plow, and a third design with 1.75-inch center-to-center spacing for heavy-duty tools, that is available in 3-ft to 4-ft lengths. Winter’s one-piece scarifier board allows back-dragging and provides an advantage over boards that have weld-on holders that can break away.

With Winter’s Carbide Matrix welding processes and hard-face technology, the scarifier teeth provide great performance and longer wear life. Further, scarifier teeth options include a universal shank mount and CAT® style carbide scarifier teeth with cast steel or Winter Carbide Matrix®. Options also include Galion® style carbide scarifier teeth with cast steel or Winter Carbide Matrix®.

Winter Equipment’s grading equipment comes with a satisfaction guarantee. If the product doesn’t perform or last as long as promised, the company will work with its customers until satisfied.

Find out more, visit, www.winterequipment.com.