In an era marked by rapid technological innovation, mechanic and service trucks have evolved from simple vehicles to highly specialized tools designed for diverse tasks. With industries growing more complex, the need for work trucks that can adapt to specific job requirements has never been greater. Today’s mechanic and service trucks are built to be more versatile, sustainable, and efficient, offering customization options that cater to the unique needs of each operator.

Innovation is reshaping fleet management, allowing businesses to optimize operations while staying ahead of regulatory pressures and sustainability goals. From modular designs to lightweight materials and eco-friendly power systems, work truck customization isn’t just about upgrading old models — it’s about redefining what a work truck can be.

MODULAR DESIGNS: TAILORING TRUCKS TO MEET EVERY NEED

Modular designs have revolutionized mechanic and service truck customization by offering unparalleled flexibility and personalization to meet the unique demands of each job. Gone are the days of one-size-fits-all vehicles. Operators can now adjust every aspect of their trucks, from shelving and toolbox systems to specialized workspaces.

One key component in this transformation is adjustable shelving systems. These systems allow operators to modify shelf heights and configurations to accommodate specific tools and equipment, boosting workspace efficiency and improving safety by keeping tools secure and accessible. If tools are well organized, operators can easily access them, increasing productivity. Many operators note that having a good organization method directly contributes to time savings when technicians can quickly find what they need.

Moreover, the flexibility of infinite shelving offers a significant advantage. Unlike standard setups that restrict how shelving is arranged, infinite shelving allows operators to customize storage locations to meet their specific needs. Whether it’s adjusting the height of shelves for better ergonomics or repositioning shelves based on changing requirements, this system ensures that the truck can be outfitted for any task. For instance, a technician can adjust the shelves to their height for easier access or even modify them as their operational needs evolve.

In addition to shelving, toolbox systems are an essential part of modular designs. Having a well-organized toolbox system with clearly labeled drawers helps reduce time spent searching for the right tools, especially when multiple users are operating out of the same truck. Plus, many manufacturers offer locks for cabinets and toolbox systems, providing added security for valuable tools and equipment. This feature is particularly useful in high-risk environments or for operators working in areas where theft is a concern, ensuring equipment remains secure when the truck is not in use.

Operators and fleet managers can customize trucks to fit individual needs or create a standard layout based on team feedback. Even with a standard setup, operators can modify the truck after delivery, adjusting shelves, hooks and racks as needed. This ease of adjustment reduces the time and cost typically spent on outfitting trucks, leading to quicker turnaround and more efficient resource use. Flexibility also extends to toolboxes and bolt bins, giving operators more control over tool and part storage.

CUSTOMIZING SPECIALIZED EQUIPMENT: COMPRESSORS, POWER SYSTEMS AND LUBE SKIDS

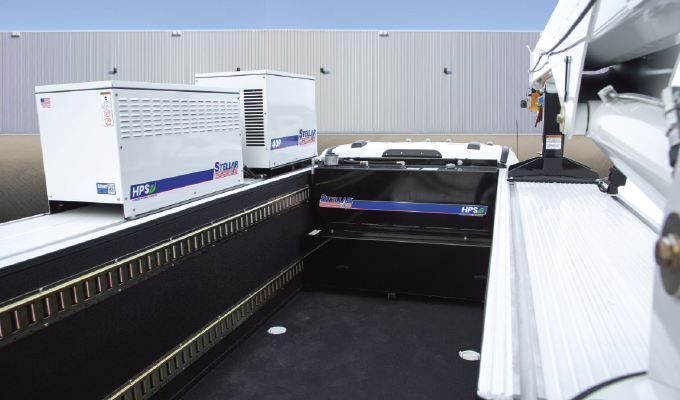

Modular designs also allow for the integration of essential specialized equipment like air compressors, hybrid power sources and lube skids. These additions ensure that mechanic and service trucks are tailored to meet the unique demands of the job while maintaining the flexibility to adjust as needs evolve.

When adding equipment like an air compressor, it’s important to ensure that the truck meets the necessary hydraulic requirements for proper operation. The type of compressor — single-stage, two-stage, or rotary screw — will influence how it integrates with the truck. Users need to consider whether the truck can support these systems or if additional modifications are needed, such as adding an air tank for piston compressors. While adding a hydraulic compressor to an existing truck setup is possible, it may require an extensive modification. Since hydraulic requirements would be changing, it is important to ensure the power take-off (PTO) and pump setup is spec’d appropriately.

For lube skids, the key consideration is ensuring that the truck can handle the necessary requirements for the equipment. As with compressors, the integration process can be straightforward if the truck is built to accommodate these systems, but special attention must be paid to weight distribution to prevent overloading the truck’s capabilities.

Hybrid power sources, using lithium-ion battery technology, are also becoming a key part of truck customization. These systems reduce fuel consumption and emissions, helping operators meet environmental goals while enhancing efficiency in demanding work environments.

One of the features that makes this customization process easier is the inclusion of mounting rails in the truck design from some manufacturers. Drill-free rails protect cabinet contents from water intrusion and provide the flexibility to add and adjust components like compressors and power systems as required, making it easier for operators to fine-tune their setups. Pass-through slots within the cabinets can also assist with wiring and cable management when integrating power systems.

For example, if the inverter is mounted at the front of the side pack and the batteries are positioned at the rear, pass-through slots on one side of the truck allow for seamless connections between the two, reducing installation complexity and ensuring an organized setup.

This level of customization ensures that the truck is not only equipped for its current tasks but can also adapt as the operator’s needs change. Whether outfitting a truck for a new service function or upgrading existing equipment, the ability to easily integrate specialized equipment maximizes the truck’s utility and longevity.

EMBRACING LIGHTWEIGHT MATERIALS FOR ENHANCED PERFORMANCE

Lightweight materials, particularly aluminum, have become a key focus in modern work truck design due to their significant advantages. Aluminum trucks and components offer reduced weight without compromising payload capacity, leading to potentially improved fuel efficiency, lower operating costs, and a smaller environmental footprint.

One of the biggest benefits of aluminum is its longer lifespan. While steel trucks may still be prevalent in certain industries, aluminum trucks are known to last longer and require fewer repairs. The superior corrosion resistance, especially in environments exposed to moisture, salt, and other harsh conditions, significantly reduces the need for maintenance and repair. Operators can expect a better return on investment, as aluminum bodies extend the life of the truck, delaying the need for costly repairs or replacements. Depending on geography and the types of jobs, aluminum trucks could last anywhere from five to 10 years longer than steel counterparts before requiring major repairs, which improves total cost of ownership over the truck’s lifecycle.

Additionally, aluminum trucks can maintain their resale value better than steel ones. When it’s time to sell or trade in a truck, aluminum bodies retain more value because they have endured less wear and corrosion, making them more attractive to buyers. This resale value is an important consideration for fleets looking to optimize their investments over time.

Beyond the financial benefits, the reduced weight also allows for higher payload capacity, meaning trucks can carry more equipment and tools without exceeding weight limits.

CUSTOMIZING THE BED AND CRANE: ENHANCING FUNCTIONALITY AND EFFICIENCY

Customization options for the bed and crane are vital in turning mechanic and service trucks into versatile, high-functioning tools tailored to specific tasks.

For the bed, sliding top covers offer protection for equipment, keeping tools and materials secure from the elements and potential theft. This is especially useful for operators who need to transport valuable gear or equipment regularly. Additionally, cabinet systems can be integrated into the bed to provide organized storage solutions. Mobile lube skids, for example, can be secured using D-rings, and track systems are available as an additional way to secure gear, ensuring safe transport while maintaining easy access to essential equipment.

A workbench bumper with an integrated full-width long bar storage compartment and vise mounts is another practical customization. Vise mounts allow operators to securely hold workpieces for field repairs or maintenance tasks, effectively turning the truck into a mobile workshop. Some larger models even offer a bumper drawer that slides out to provide additional storage space, improving convenience and organization on the go.

When it comes to cranes, one key customization is the addition of boom tip lights, typically LED for maximum visibility. These lights enhance safety and precision, especially during night operations, allowing operators to clearly see the load being lifted and positioned, even in low-light conditions.

These customizable features transform mechanic and service trucks into more efficient, safer, and adaptable tools that can meet the changing demands of the jobsite.

COMFORT, USABILITY AND PRODUCTIVITY AT THE FOREFRONT

Operator comfort and usability are crucial for maximizing productivity, especially during long hours. Simple, intuitive tools and systems streamline workflows, allowing operators to focus on their tasks. For instance, ergonomic bale-style pull-handles on toolbox systems reduce physical strain and speed up workflow by allowing operators to open drawers with one hand and in a natural hand position.

Ease of use also simplifies training for new employees, helping them become productive quickly and reducing downtime. These features not only optimize productivity but also enhance operator satisfaction, leading to improved employee retention and operational success.

SHAPING THE FUTURE OF WORK TRUCKS

The work truck industry is evolving rapidly, with innovations like modular designs that enable operators to optimize fleets for maximum efficiency, driving a competitive edge in a fast-changing market.

about the author

Tyler Havens is the product manager at Stellar. To learn more, visit www.stellarindustries.com.