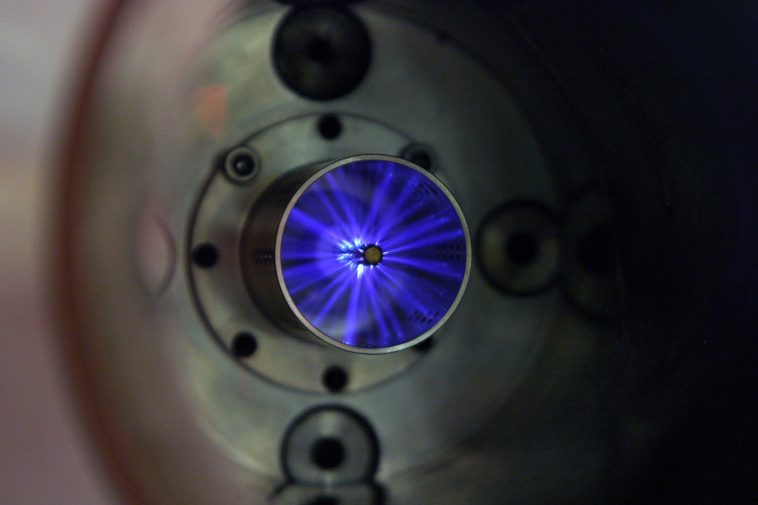

Transient Plasma Systems Inc. (TPS), which develops nanosecond pulsed plasma ignition systems to improve fuel efficiency and reduce greenhouse gas emissions, achieved a new milestone in internal combustion engine testing.

The new TPS test marks the first multi-cylinder demonstration of the company’s nanosecond pulsed plasma ignition technology in a mass-manufactured, on-road natural-gas engine. TPS tested its Transient Plasma Ignition System in multi-cylinder operation on a Cummins Westport ISX12N natural-gas engine.

“The successful multi-cylinder testing of nanosecond pulsed plasma ignition technology gets us one step closer to widespread market demand and adoption. We are very grateful to the California Energy Commission (CEC) for providing the grant, to Cummins Westport for providing the engine and engine support, and to SoCal Gas for providing additional funding for this effort,” Dan Singleton, co-founder and CEO of Transient Plasma Systems, says.

The tests were conducted at the US Department of Energy’s Argonne National Laboratory in Illinois, under a grant by the CEC with support from SoCalGas and Cummins Westport.

“This is a major milestone in the development of our nanosecond pulsed plasma ignition technology,” Jason Sanders, co-founder and chief scientist at Transient Plasma Systems, says. “Our ignition technology reduces fuel consumption in combustion engines by a significant amount, and it can do so with an easy-to-implement solution that requires no engine redesigns.”

The testing demonstrated stable operation of the Transient Plasma Ignition System under on-road conditions, including improved brake thermal efficiency, reduced CO and NOx emissions, and extension of exhaust gas recirculation (EGR) dilution tolerance.

Find out more, visit www.tpsignition.com.