The electrification of commercial fleets presents a chicken-and-egg dilemma that keeps fleet managers awake at night: commit to electric vehicles without proven charging infrastructure or investing in charging infrastructure without a clear EV adoption timeline. For work truck operations where every minute of downtime translates to lost revenue; this uncertainty isn’t just inconvenient, it’s a business risk.

Enter Lincoln Electric, a company that spent the last 130 years perfecting high-power electronic equipment for the harshest industrial environments. Their Velion DC fast charging platform is the first charging solution engineered specifically for the punishment that work truck fleets dish out daily.

“We’re not newcomers trying to figure out power electronics,” says Michael Peash, OEM account manager for for Lincoln Electric EV charging. “We’ve been manufacturing inverter systems that operate 24/7 in steel mills, construction sites and offshore platforms for decades. That same DNA is built into every Velion charger.”

NATURAL EVOLUTION

connector on the left side and a NACS connector on the right side with 12 feet cables capable of delivering 300 amps of current.

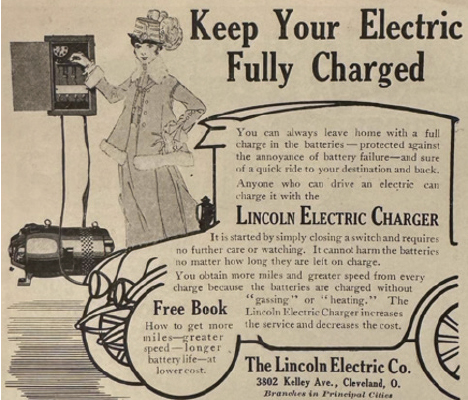

Founded in 1895, and known in the work truck world primarily for welders, Lincoln Electric has deep historic ties to the very first generation of EVs. The company manufactured EV charging systems in 1914 for the Baker Electric automobile, before internal combustion made electric propulsion commercially obsolete. That firsthand legacy informs the company’s 21st century approach.

Lincoln Electric’s entry into EV charging might surprise those unfamiliar with the company’s deep expertise in power conversion technology. Yet for those who understand the technical requirements of DC fast charging—managing massive electrical loads, converting AC to DC power efficiently and operating reliably in extreme conditions—the connection becomes obvious.

The company’s inverter-based welding systems already perform similar electrical gymnastics, converting AC utility power into precisely controlled DC output thousands of times per day and around the globe in its welding equipment. This isn’t theoretical knowledge gained from designing consumer products; it’s experience from equipment that must perform flawlessly when failure means shutting down production lines or construction projects.

The Velion platform leverages this heritage in two distinct configurations designed for different fleet needs. The 150kW DC fast charger pedestal delivers Level 3 charging capability with 200-1000V DC output range, accommodating every EV battery configuration currently on the market. Operating from -31°F to 122°F with over 95 percent efficiency, the system achieves what Peash describes as “the sweet spot between charging speed and infrastructure requirements.”

For operations requiring flexibility, the 50kW mobile DC fast charger is mounted on wheels with an optional roll cage for job site protection, this unit delivers scalable power output (12.5kW, 25kW, or 50kW) while maintaining the same industrial grade components as its larger sibling.

MORE THAN THE SUM OF ITS PARTS

Lincoln Electric’s July 2024 acquisition of Vanair Manufacturing represents more than corporate expansion, it’s a strategic alignment that directly benefits work truck fleets. Vanair’s 53-year reputation in the service truck market, combined with their nationwide network of authorized dealers and service centers, provides the distribution and support infrastructure that fleet operators demand.

“The synergy between Lincoln Electric and Vanair creates something unique in the market,” says Peash. “Fleet managers now have access to Velion chargers through the same Vanair dealers who’ve been servicing their work trucks for decades. These aren’t consumer electronics retailers trying to understand commercial operations, they’re partners who speak the language of uptime and understand that a charger down means trucks aren’t rolling.”

This distribution strategy addresses a critical gap in the commercial charging market. While consumer EV charging networks focus on retail locations and highway corridors, work truck fleets need local partners who understand their operational requirements and can provide rapid service response. Vanair’s dealer network, already embedded in the work truck ecosystem, provides exactly that capability.

Integration goes deeper than distribution. As one fleet customer recently noted about their Lincoln-Vanair equipment: “As a new member, Vanair’s equipment is now synonymous with Lincoln’s systems, which was important since both brands are well respected in our industry.” This brand equity matters when fleet managers stake their operations on new technology.

ENGINEERED FOR UPTIME

The Velion platform’s engineering specifications read like a wish list from fleet maintenance managers. The NEMA 3R enclosure rating ensures operation in outdoor environments, while the IK08 impact rating means the equipment can withstand the inevitable bumps and collisions of a working environment. Potted printed circuit boards, a technique borrowed from military and marine applications, protect sensitive electronics from moisture and vibration.

Perhaps most importantly, the modular design philosophy extends throughout the system. The 150kW charger separates the power tower from the dispenser, allowing installation flexibility with up to 200 feet of separation. This means fleet operators can position power equipment in protected locations while placing dispensers in convenient charging positions. When service is required, modular components enable rapid replacement rather than lengthy repairs.

“Downtime isn’t an option for work truck fleets,” says Peash. “That’s why we engineered the Velion with the same approach we use for welding equipment that operates in 24/7 production facilities. Every component is selected for durability, every connection is designed for repeated use, and every system includes redundant protection circuits.”

The mobile 50kW unit takes this reliability focus even further. Recognizing that mobile chargers face unique challenges, from job site debris to frequent transport, Lincoln Electric incorporated features like lifting eyehooks for crane operation, integrated cable management, and adjustable power output to match available electrical service. The optional roll cage isn’t an afterthought; it’s recognition that in a work truck environment, equipment often takes a beating.

MEETING FEDERAL REQUIREMENTS AND BEYOND

With federal infrastructure funding increasingly tied to domestic content requirements, the Velion platform’s American manufacturing becomes a competitive advantage. The 150kW charger exceeds 75 percent domestic content, surpassing National Electric Vehicle Infrastructure (NEVI) program requirements. The 50kW mobile unit maintains over 70 percent domestic content while meeting all Build America, Buy America (BABA) standards.

Compliance represents the minimum bar, not the target. Lincoln Electric’s Cleveland-area manufacturing facilities produce tens of thousands of inverter systems annually, providing the scale and expertise to support rapid deployment as fleet electrification accelerates. This domestic production capacity also enables customization, from dispenser branding to specific connector configurations, that offshore manufacturers struggle to match.

REAL-WORLD APPLICATION

The true test of charging infrastructure comes not from specification sheets but from daily operation in fleet environments. Consider a typical municipal fleet scenario: trucks need charging between shifts, often outdoors, in locations where electrical infrastructure varies, and where different vehicle types require different charging speeds.

The Velion’s scalable power output addresses this complexity directly. A fleet can set its 50kW mobile charger to 25kW output when connected to limited electrical service, then move the same unit to its main facility for full speed charging. The ability to limit power draw prevents overloading circuits while maintaining charging capability, a crucial feature for operations with aging electrical infrastructure.

For dealer service departments, the mobile unit’s versatility proves invaluable.

“Dealerships are seeing increasing numbers of electric commercial vehicles coming in for service,” says Peash. “With a 50kW mobile charger, they can charge customer vehicles in service bays, move the Velion unit to overflow lots during busy periods, or even take it to customer locations for emergency charging support.”

The 150kW stationary system, meanwhile, excels in depot charging scenarios where multiple vehicles need sequential charging. The 15-inch high-contrast touchscreen remains readable in direct sunlight, while tactile buttons ensure operation even when technicians wear work gloves. The overhead status indicator light, visible from across a parking lot, eliminates the guesswork of determining charger availability.

SERVICE AND SUPPORT INFRASTRUCTURE

Lincoln Electric’s nationwide service network, expanded through the Vanair acquisition, provides multi-tier support for Velion installations. Factory-trained technicians at regional service centers can diagnose and repair systems, while the modular design enables fleet maintenance staff to perform basic component swaps with minimal training.

The company backs this support infrastructure with a three-year standard warranty, with options to extend to five or 10 years–exceeding typical charging equipment coverage, and maintains substantial parts inventory domestically. This combination of warranty protection and parts availability addresses fleet managers legitimate concerns about being early adopters of charging technology.

A 130-YEAR STORY CONTINUES

As work truck fleets navigate the complex transition to EVs, the need for industrial grade charging infrastructure becomes increasingly apparent. Many of the charging solutions being offered to work truck fleets simply cannot match the duty cycle requirements of commercial operations.

For fleet managers evaluating charging options, the message is clear: the same company that’s powered the American industry for 130 years now stands ready to power its electric future. With the Velion platform, that future charges ahead on a foundation of proven reliability, domestic manufacturing, and unmatched support infrastructure.

“We’re not asking work truck fleet managers to bet on an unproven startup or offshore manufacturer. We’re offering the combined reliability of Lincoln Electric and Vanair and charging solutions engineered specifically for the realities of work truck operations. That’s a combination you won’t find anywhere else in the market,” says Peash.

for more information

To learn more, visit www.lincolnelectric.com/en/ev-charging/ or www.vanair.com/lincolnelectric-velion-ev-chargers/.