Fleets that require auxiliary power, listen up! The electrical systems and products you choose for your vehicles can make a significant impact on the efficiency of power output and operating costs. Mitul Chandrani of Mission Critical Electronics shares more about how the latest DC and AC-power technology solutions can improve your operation and why it pays to invest in quality products and systems.

FOR OUR READERS WHO ARE UNFAMILIAR, WHAT IS MISSION CRITICAL ELECTRONICS AND XANTREX?

CHANDRANI: Mission Critical Electronics (MCE) represents a platform of distinctive brands and products focused on industrial electronics and electrical applications with an emphasis in the trucking industry. MCE provides specialized products for critical systems in a wide variety of applications operating under leading brands including, American Battery Charging, ASEA Power Systems, DuraComm, Kussmaul Electronics, Newmar Power, Purkeys, Power Products Unlimited, ZeroRPM, and Xantrex.

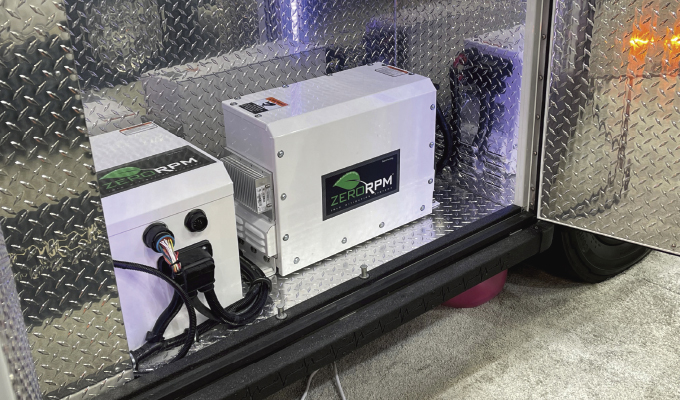

Xantrex is a leading supplier of onboard DC and AC-power technology and offers products such as inverters, battery chargers, lithium-ion batteries, solar solutions, and more for commercial and recreational vehicles. Xantrex has a long history of working in the commercial trucking industry. In fact, Xantrex was the first company to manufacture inverters specifically for heavy-duty trucks. Xantrex custom designs inverters for all major OEMs including Peterbilt, Volvo, and International. Xantrex is closely aligned with ZeroRPM, a company that is creating alternative solutions to idling by turning commercial vehicles into hybrids through its idle mitigation system.

HOW CAN XANTREX BENEFIT FLEET OPERATIONS?

CHANDRANI: Xantrex offers several high-quality AC power technology products. Our inverters are especially popular among drivers and truck owners looking to effectively convert DC power to AC power. When it comes to cost-cutting opportunities, one technology we’re particularly excited about is our Freedom eGen Lithium-Ion system. The primary components of the Freedom eGen system consists of a lithium-ion battery pack, inverter/charger, auxiliary alternator, and solar wherever possible. This system is a compelling alternative to generators and engine idling to power jobsite and work tools, which helps reduce fuel costs, emissions, and noise pollution. A Li-Ion battery pack delivers six to eight times the life of traditional lead-acid batteries and can be drawn down much further into the battery bank.

The system is regulated by Xantrex’s Intelligent Battery System. Freedom eGen supports charging from a second alternator, which is recommended for charging of lithium-ion batteries or shore power when needed. When this system is paired with our solar panel solutions, the continual trickle charge provides a boost in power to draw from on the jobsite operation of tools and equipment. Since idling burns roughly a gallon of diesel per hour, this solution is designed to reduce expenses for fleets and help them operate more sustainably over the long run.

THE XANTREX WEBSITE MENTIONS A “COMPLETE POWER ECOSYSTEM” FOR WORK TRUCKS. CAN YOU EXPLAIN THAT FOR OUR READERS?

CHANDRANI: Xantrex’s key products, such as its batteries, inverter/chargers, and solar solutions are all connected and designed to be monitored and configured through an app or web browser offering a convenient and user-friendly experience. For example, a customer can see exactly how much battery capacity is left on their phone and check to see if their inverter is providing enough power or the exact amount it’s emitting to ensure it can power electronics. For those using our solar solutions to trickle charge batteries, you can even monitor the amount of power solar panels are generating to charge them.

Since these products are all designed to seamlessly work together, it’s easier to monitor any issues that come up with a specific product and diagnose what’s going on. For work truck owners that equip their trucks with these products as part of the Xantrex/ZeroRPM Idle Mitigation System (IMS), they can even monitor and see their fuel and maintenance savings per vehicle and also for the entire fleet in an easy-to-understand dashboard. They can also see how much idle time has been saved and tons of CO2 that is prevented from going into the atmosphere. This data is very powerful for fleet and operations folks to justify the investment in such systems. With higher fuel prices, the payback period may be one to two years in most work truck applications.

WHAT ARE THE MAIN DIFFERENCES BETWEEN LI-ION AND TRADITIONAL LEAD-ACID BATTERIES? IS SWITCHING TO LI-ION BATTERIES AS A GENERAL REPLACEMENT WORTH IT?

CHANDRANI: Lithium-Ion batteries are growing in popularity as an alternative to traditional batteries to power on-board electronics. The main reason that lithium batteries are such a game changer is that they can be completely discharged without damage and provide more cycles than the typical deep cycle battery. So, if you have a 600-amp hour lithium battery, you have 600-amp hours of usable power. Lead-acid batteries, on the other hand can only be discharged 50% at most without causing them damage.

Most commercial vehicles have 400-amp hour battery banks, which only gives you 200-amp hours of usable power. Making that even less effective, most OEMs only allow you to discharge the batteries to a 30% state, so in that case, you’re hardly getting any usable battery power at all. As the world’s lightest metal, lithium provides a huge weight advantage. Li-Ion batteries are 60 to 80% lighter than their lead counterparts. A typical Group 31 battery weighs about 75 lbs while a similar Li-Ion battery only weighs 28 lbs. Li-Ion batteries cost more upfront than traditional batteries, but the additional life cycles and amount of power work trucks can draw before idling would be needed to recharge these batteries can save significant costs over its life.

YOU MENTIONED XANTREX AND ZERORPM ARE CLOSELY ALIGNED. IN WHAT WAY?

CHANDRANI: ZeroRPM offers a solution that essentially turns diesel trucks into hybrids through its idle mitigation system when in park. The ZeroRPM system uses lithium-ion batteries to provide the power needed for tools and for heating and air conditioning in the cab. It also helps make the onboard power system run quietly and more efficiently. Once a work truck is in park, the system shuts down the engine and provides all power from the Li-Ion battery. During extended stationary use, the system manages start/stop to recharge the batteries as needed. This solution is especially useful for work trucks, such as sewage vacuum trucks, bucket trucks, service vehicles, or trucks using high-powered hydraulic systems like cranes to supply the necessary power without needing to constantly idle or connect to shore power. It can help save trucks hours per day in idle time.

CAN YOU SHARE ANY CASE STUDIES OR SUCCESS STORIES FOR FLEETS USING XANTREX TODAY?

CHANDRANI: We have a city in Texas that operates 40 trucks including ambulances all equipped with ZeroRPM, and the savings they’re getting from the ZeroRPM idle mitigation system are tremendous. The vehicles often run double shifts, and over an 11-week period collecting data from the fleet, we found that the city mitigated more than 28,000 hours of idle time, which helped them save more than $86,000 in fuel expenses. Not only that, but the city was also able to eliminate 272 short tons of carbon, which is equivalent to powering 48 homes for an entire year. To see what kind of savings your fleet might be able to achieve by using ZeroRPM, we recommend inputting your fleet’s information into our ZeroRPM work truck calculator on our website: www.missioncritical.zerorpm.com/landing.

BATTERIES, INVERTERS, AND BATTERY CHARGERS VARY GREATLY IN QUALITY AND PERFORMANCE. CAN YOU TALK ABOUT THE TRADE-OFFS THERE ARE BETWEEN BUYING THESE PRODUCTS THAT ARE “PREMIUM” VS “BUDGET?”

CHANDRANI: We’ve all heard the expression “you get what you pay for.” In some cases, buying on price makes more sense than buying something that costs more because the benefits of the higher quality product aren’t noticeable enough to justify the premium cost. But, when it comes to spec’ing your work trucks with power solutions, going with the cheapest options available may prove to be more costly in the long run. Traditional AGM or lead-acid batteries need to be replaced more often than premium lithium-ion batteries. You should expect a lead-acid battery to last 400 to 500 cycles, whereas a quality lithium-ion battery may last 4,000 to 5,000 cycles depending on the use. You can often tell the quality of the battery by the length of its warranty. Xantrex offers a 10-year warranty on all its lithium-ion batteries.

When it comes to inverters, “budget” options may not be robust enough to withstand a sudden inrush of current required to start high-powered tools or equipment, which may end up damaging electronics. A premium inverter would shut down if the inrush of current is too much, which helps prevent damage to downstream loads. What’s more, for work truck operators powering a variety of high-powered tools or equipment, extended surge power is needed. A compressor might need 5 to 9 seconds for example, so you need an inverter that can handle that duration. So, it’s important to check surge power ratings. Low-end inverters often don’t clearly state output performance. All Xantrex inverters list this information so you can match the exact power output specifications you need for your operation.

FOR MORE INFORMATION

Mitul Chandrani has worked in the trucking industry for close to 15 years. He manages the marketing function for Xantrex, ZeroRPM, Purkeys brands, and its parent company Mission Critical Electronics. Chandrani also helps manage Xantrex’s Youtube channel, which contains a repository of technical and how-to videos on power solutions. Find out more, visit www.mission-critial-electronics.com.