Although gas prices aren’t rising at the rate they were even a few weeks ago, fleets are still affected by the costs of fueling their vehicles. As gas prices continue to remain high, is there anything fleet owners can do to find relief? Branden Harbin, the executive director of global marketing at Allison Transmission, says the company has a solution: its FuelSense 2.0.

WHAT EXACTLY IS FUELSENSE 2.0?

HARBIN: FuelSense® 2.0 uses a set of algorithms within Allison electronic controls to deliver quantifiable fuel savings of up to 6% without sacrificing performance.

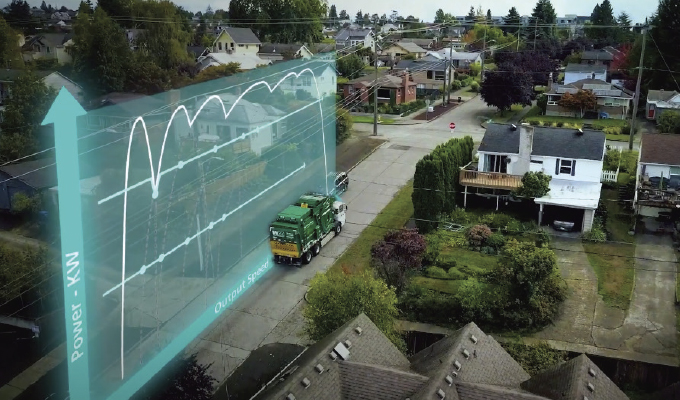

A key feature of FuelSense 2.0 is DynActive® Shifting, an innovative shift scheduling technology that uses an algorithm to choose the most efficient shift points based on the customer’s specifications, vehicle, and environmental parameters. Compared to older shifting technologies, which used shift schedules with fixed shift points, transmissions equipped with DynActive Shifting can continuously deliver the ideal balance of fuel economy and performance based on dynamic and real-time inputs.

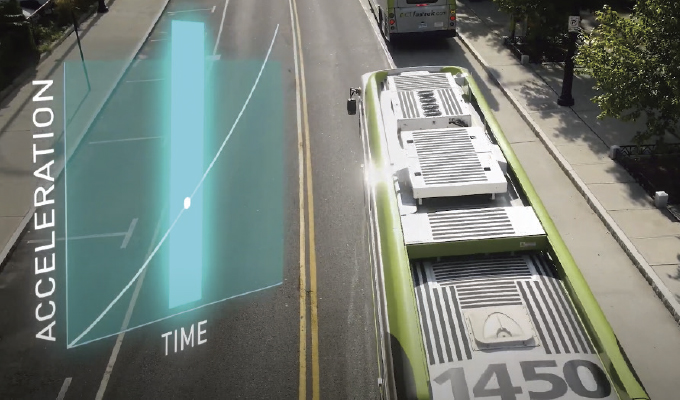

FuelSense 2.0 also enables vehicles to operate in Neutral at Stop, when in traffic or at a traffic light, which reduces fuel consumption and emissions by decreasing or eliminating the load on the engine when the vehicle is stopped. In addition, the Acceleration Rate Management feature mitigates aggressive driving by automatically controlling engine torque to one of five available levels of engagement, precisely managing vehicle acceleration to a calibrated rate.

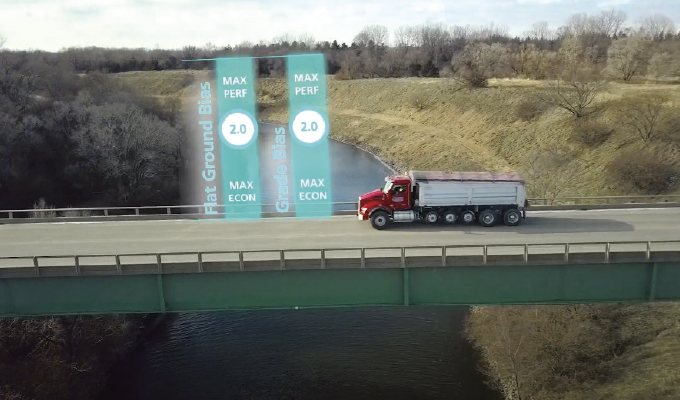

Lastly, Dynamic Shift Sensing allows a vehicle to toggle between performance and fuel-economy-biased shift schedules, providing further flexibility in vehicle configuration based on current vehicle load combined with the capabilities provided by the rest of the FuelSense features.

FuelSense 2.0 provides impressive fuel savings, all while maintaining the traditional advantages of a fully automatic transmission including optimized drivability, maneuverability, reliability, durability, and productivity.

CAN ALL ALLISON TRANSMISSIONS BE EQUIPPED WITH DYNACTIVE SHIFTING AND FUELSENSE 2.0?

HARBIN: The FuelSense 2.0 calibration can be integrated into Allison Transmission’s 1000 Series™ and 2000 Series™ transmissions, which are designed for light commercial vehicles, Allison 3000 Series™ transmissions developed for medium-duty commercial vehicles, and Allison 4000 Series™ transmissions, which are purpose-built for heavy-duty vehicles.

IS THIS SHIFTING TECHNOLOGY SUITED TO ALL VEHICLE CLASSES OR IS IT SPECIFIC TO MEDIUM-DUTY OR HEAVY-DUTY VEHICLES?

HARBIN: As noted above, FuelSense 2.0® can be specified for Allison transmissions that support both medium- and heavy-duty vehicles. The technology is ideal for on highway applications, including vocational trucks. FuelSense has demonstrated the highest potential fuel savings in the demanding duty-cycles of distribution, city transit, refuse, and construction applications because of their frequent stop-start needs.

HOW DOES THIS TECHNOLOGY HELP SAVE MONEY AT THE PUMP?

HARBIN: Through its proprietary algorithms within the electronic controls, FuelSense 2.0 provides impressive fuel savings for the demanding duty-cycles of commercial fleets. As outlined above, this innovative solution chooses the optimal shift point for vehicles in order to reduce fuel consumption combined with the flexibility to customize based on specific vehicle characteristics. It also enables vehicles to operate in neutral when stopped, which further trims fuel consumption and emissions by reducing or eliminating the load on the engine.

On average, Allison FuelSense 2.0 can save medium-duty fleets $2,000 per truck per year by spec’ing a FuelSense calibration when the truck is ordered. Assuming that the truck is maintained for eight years in the fleet, that’s $16,000 in savings, simply through a software calibration. By comparison, FuelSense typically costs $500 or less when ordered with a new truck, or when an existing truck is reprogrammed to include a FuelSense calibration. That recalibration process can often be completed in under 20 minutes.

OEMs are beginning to evaluate electric vehicle capabilities driven by advancements in EV technology and upcoming changes to regulatory requirements, but there is much that can be done now to make the current generation of conventional vehicles cleaner and more fuel efficient. FuelSense 2.0 is an example of technology that can be integrated into transmissions now to help fleets reduce fuel consumption and emissions.

ASIDE FROM FUEL SAVINGS, ARE THERE PERFORMANCE BENEFITS TO FUELSENSE 2.0 TECHNOLOGY?

HARBIN: Yes, FuelSense 2.0 allows fleets to optimize both fuel economy and performance to meet their specific needs. In particular, DynActive Shifting enables vehicles to operate at peak efficiency, no matter the driving conditions. Through this algorithm in the calibration, fleets will save on fuel while maintaining the industry-leading performance they’ve come to expect from Allison propulsion solutions.

HOW CAN FLEET OWNERS GET THIS TECHNOLOGY INTO THEIR TRUCKS?

HARBIN: Fleet owners are encouraged to contact their Allison representative to discuss specifying FuelSense 2.0 for their trucks. They can also learn more about this innovative software solution by visiting the Allison Transmission website.

FOR MORE INFORMATION

Branden Harbin serves as global head of marketing and external communications for Allison Transmission, a position he has held since 2019. Over the course of his career with Allison, which began in 2009, Harbin has served in a variety of positions across several different areas of the business including marketing, sales, strategy, finance, and operations. Prior to his current role at Allison, Harbin served as director of North America national account sales. Before joining the company, Harbin worked at public accounting firm KPMG, focusing on audit and advisory services in the transportation and government sectors. Harbin earned a bachelor’s degree in accounting and finance from the Kelley School of Business at Indiana University and a master’s in business administration from Butler University. Find out more about ways to save money at the pump and improve vehicle performance, visit www.allisontransmission.com.