Cost increases and shortages of labor are burdening snow removal services in big cities and small towns alike, all while climate change has increased snowfall levels around the country. For example, according to an article that appeared on MinnPost.com, Minneapolis has experienced the most early-season snowfall in this past winter since the 2010-2011 season. The article also reported that the high volume of snowfall this year has reinforced a demand for sidewalks and streets to be plowed for pedestrian and driver safety. This often requires the use of a dependable fleet of snowplow trucks.

As snow removal fleet demands increase, it’s imperative that commercial emergency vehicles are properly cared for and managed to help ensure optimal performance when called to the job. This includes maintaining one of the most important internal components: the battery.

FLEET MAINTENANCE

Fleet owners and operators must care for and maintain vehicles that are often subjected to harsh winter conditions. Among the concerns for fleet maintenance is the vehicle’s battery. Lead acid batteries, which are often used, typically lose some of their functional capacity when exposed to low temperatures. At 0 degrees Fahrenheit, for example, the power drops by about 30%. As the oil thickens in the cold, the battery must work harder to start the engine. Additionally, when vehicles run in low temperatures, they can reveal previously hidden battery damage from the high temperatures during the summer.

Proper care and maintenance are necessary to help ensure that the fleet’s vehicles operate reliably, but this care and maintenance entail increasingly scarce labor and rising material costs. Replacement and installation of a battery that fails while the truck is in the garage will incur time and costs, but if the battery fails during operation, the truck can break down and stop the job altogether.

Consistent monitoring of the truck’s operation can minimize the risk of battery failure, so any sign of compromised performance should be immediately investigated. The battery’s condition will influence how well the engine and onboard accessories operate. Some signs that a vehicle’s battery needs attention include dimming headlights and slow starting.

In preparation for winter, the battery should be inspected, cleaned, tested, and, if necessary, fully charged or replaced. The following guidelines can help keep the battery in good condition and proper working order.

Inspection

Safety precautions include proper personal protective equipment for the eyes and hands and insulated tools to prevent short circuits.

- Check the electrolyte level if the battery is a conventional flooded lead acid battery and replenish the cells with distilled water, if needed.

- Examine the case, terminals, cables, and clamps for signs of damage, excessive wear, and corrosion. Corrosion can appear as a thin, white powder or a blue-green growth. Make sure all connections are secure. Replace fraying or cracked cables to prevent a short circuit. Replace corroded clamps, as well. If the case is cracked, leaking, or if the terminals are damaged, replace the entire battery.

Cleaning

It is important to keep the battery’s case and terminals free of accumulated dirt, corrosion, and acid film to prevent current losses.

- Disconnect the battery before cleaning.

- Clean dirt away from cables and connectors. Use diluted ammonia or a paste of one part baking soda to three parts water to remove acid film.

- Remove deposits from terminals with a battery terminal brush or emery cloth.

- Wipe grime from the case and clamps with water.

- Rinse and dry.

- Reconnect the battery.

- Coat terminals with dielectric grease, anti-corrosion spray, or petroleum jelly to minimize further deposits.

Testing

A digital voltmeter measures the Open Circuit Voltage (OCV) to determine the battery’s State of Charge (SOC). Wait at least six hours after the battery has been charged to perform this test. This interval is necessary for an accurate reading, which can be taken only after the chemical reactions in the battery reach an equilibrium and the surface charge is gone. The manufacturer’s specifications will indicate the proper charge current required to fully charge the battery.

Charging

Proper charging may help to make sure that the battery performs for its entire intended service life.

- A full charge will minimize sulfation, which is the accumulation of lead sulfate crystals on the plates when the battery is persistently undercharged. Sulfation reduces available plate surface area and interferes with the battery’s ability to hold a charge.

- A full charge will also prevent the battery from freezing in low temperatures.

- If the battery discharges to below 50% SOC, the engine may not start.

- Each battery chemistry has its own charging requirements, so consult the battery manufacturer’s specifications for the proper charger type and current. The current must be high enough to fully charge the battery, but not so high that the battery overheats.

IMPROVE RELIABILITY

A necessary battery replacement can be an unexpected cost, but it also can be an opportunity to improve reliability.

In addition to starting the engine, batteries used in snowplow trucks need to provide power to operate onboard accessories, known as hotel loads. Power drain from hotel loads can shorten the life of a conventional battery. Dual-purpose batteries, on the other hand, are designed for deep cycling that can power an increasing number of hotel loads, including Global Positioning Systems (GPS), communications, and climate control. Many drivers are using batteries, like ODYSSEY® batteries from EnerSys®, with enough deep cycling capacity to power hotel loads, including the heater, even with a turned-off engine.

BATTERY TECHNOLOGY

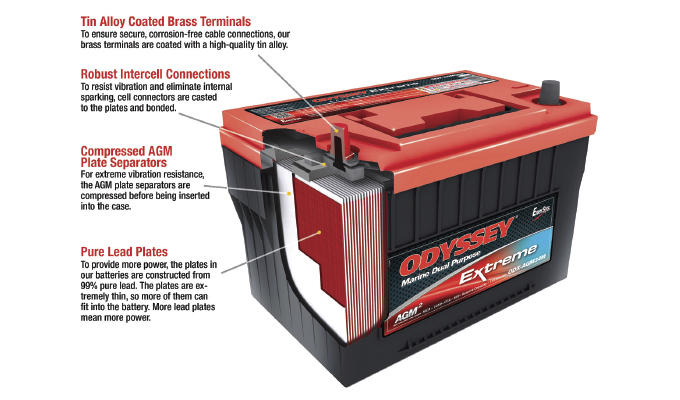

Lead acid batteries use plates made of an alloy of lead and antimony or calcium as electrodes and a solution of sulfuric acid and water as the electrolyte. The most common type is the flooded lead acid battery. Other types of lead acid batteries include Absorbed Glass Mat (AGM) batteries, which offer more advantages, such as greater cranking current capacity. Unlike flooded lead acid batteries, AGM batteries are sealed and do not require adding distilled water to the cells. This makes them virtually maintenance-free, which provides savings in labor and downtime. The plates are packed tightly in the case with absorbent fiberglass separators that hold the electrolyte. This construction not only helps keep the plates securely in place, but also maintains consistent contact between the plates and the electrolyte. This design makes AGM batteries resistant to mechanical vibration and high-impact shock, which are leading causes of premature battery failure. In addition, AGM batteries do not leak or spill electrolyte, even if the battery case is cracked or broken.

Advancement in AGM technology led to the development of Thin Plate Pure Lead (TPPL) batteries, such as ODYSSEY batteries. TPPL batteries are AGM batteries that feature plates made of pure lead, instead of alloys, which eliminate the risk of galvanic corrosion that occurs when two different metals are in contact and submerged in sulfuric acid. Pure lead also reduces the risk of sulfation. Another advantage of pure lead plates is that they can be made thinner, so more fit into the same footprint of a comparably sized, conventional lead acid battery. The additional plates provide greater surface area for the electrochemical reactions with the electrolyte to produce double to triple the cranking power of conventional lead acid batteries as well as superior deep cycling capacity.

PREMIUM BATTERIES

If the battery needs replacement, a premium TPPL battery will provide greater power and longevity than conventional lead acid batteries. ODYSSEY TPPL batteries also perform in temperatures as low as -40 degrees F and can fully recharge in as little as four hours. Even though they require a greater initial cost investment than conventional batteries, TPPL batteries save time by reducing maintenance and requiring less frequent replacement. Their rugged construction enables them to provide up to 10 years of service life. The shelf life of TPPL batteries is as much as two years when stored on open circuit (i.e., nothing connected to the terminals).

Municipalities must respond to increasing demands for snow and ice removal while containing costs and facing labor shortages. Additionally, climate change increases the severity of weather, which further complicates the management of snow and ice removal. TPPL batteries offer premium power, reliability, and cold weather resistance to reduce the risk of unplanned downtime. Today’s batteries also must have enough deep cycling capacity to support the growing number of hotel loads, even when the engine is turned off to comply with idling restrictions. Dual-purpose TPPL batteries, like ODYSSEY batteries, can be invaluable assets in the effective deployment of snow emergency vehicles. To protect this investment, fleets must be equipped with batteries that are routinely and thoroughly inspected and cared for, regardless of type.

ABOUT THE AUTHOR

Vicki Hall is the director of transportation technical solutions at EnerSys. EnerSys manufactures and distributes energy systems solutions and motive power batteries, specialty batteries, battery chargers, power equipment, battery accessories, and outdoor equipment enclosure solutions to customers worldwide. Find out more, visit www.enersys.com.