Most, if not all, work truck fleet managers have been caught in the middle of this all too familiar conundrum regarding new technology equipment deployments: Do we deploy using in-house vehicle maintenance staff? Or do we hire outside “help” to get the fleet deployed?

A simple answer is, “Of course, use the in-house maintenance staff. It’s easier, less costly, and already in place.”

“Not so fast”, says the ROI specialist from the controller’s office, “there are situations where it’s definitely more cost effective and faster to use a third-party installation company”.

This is the conundrum that American Electric Power (AEP) faced a few years ago when they decided, after much analysis and field testing, to approve the purchase and deployment of a vehicle-mounted cellular booster system to aid their iPad equipped technicians and repair crews in extending their cellular communications reach into sparsely covered rural and small-town locations. AEP’s eight wholly owned electricity generating operating companies (OPCOs) maintain over 3,500 service trucks in an 11-state area.

From our perspective, there are nine distinct functions involved in developing a fleet technology deployment plan that a fleet procurement team should follow at a minimum:

- In-house or third-party

- Your fleet’s unique requirements

- Developing the RFI

- Issuing an RFP

- RFP response

- Pilot acceptance test

- Statement of work with a detailed deployment plan

- Installation schedule, onboarding, and roll-out

- Lesson’s learned

DETERMINING INSTALLATIONS

While AEP maintains a fleet maintenance staff throughout each OPCO’s operating territory, they decided taking maintenance personnel off their primary maintenance schedule would take an inordinately long period of time to deploy the boosters. Also, having trucks drive to the maintenance garages to complete the deployment would be a slow, and time-consuming process. More importantly though, corporate procurement determined fleet maintenance would be materially affected by the addition of the booster installations and compounded by the removal of fleet vehicles from servicing electrical customers for a half day or more.

FACTORING UNIQUE REQUIREMENTS

The devil is most certainly in the details when analyzing the pros and cons of using an outside installation company. Each fleet has its own unique operating requirements that largely define whether to use an outside installation company’s service. Therefore, AEP embarked on a mission to determine whether there existed an installation company that could meet the following requirements:

- Operate within AEP’s operating footprint across the Midwest and Southeastern US.

- Manage and maintain mobile technicians that can perform installations at over 225 AEP locations.

- Design a deployment schedule that can be completed either before or after vehicles return from daily service.

- Meet the background search requirements for their technicians to come onto AEP property.

- Has a safety and drug testing program in place that meets AEP’s strict guidelines.

- Provide the required general liability, garage liability, and workers’ compensation policies to permit them to work in ALL of AEP’s operating states.

- Provide electronic gathering of vehicle VIN, fleet numbers, booster serial numbers, and pictures.

- Provide a scheduling support staff to contact AEP location representatives to confirm scheduled installations and equipment availability prior to arrival.

- Has the background and history working in vehicles owned by large utility, telco, or construction companies.

- Has verifiable references from other utility companies where they have successfully completed a multi-state, fleet technology deployment in the past 36 months.

- The financial resources to deploy numerous technicians to complete a 3500+ vehicle deployment within six months.

- Provide an installation warranty.

DEVELOPING THE RFI

After researching various “installation companies”, AEP Corporate Procurement reached out to MOBILE with a brief RFI (Request for Information) to determine whether MOBILE could in fact meet AEP’s unique requirements for a full deployment of Weboost’s cellular booster equipment. We responded within a few days to the RFI answering all the questions they had regarding MOBILE’s capabilities, references, and unique requirements.

ISSUING THE RFP

After reviewing our RFI response, corporate procurement reached out to me to inquire whether we could provide a detailed price quote for installation with a recommended deployment plan for 800-900 installations. We could, provided they send us three critically important documents from which to develop a comprehensive deployment plan:

- A spreadsheet list of all the vehicles by make, model, year, fleet number, VIN, and assigned address location.

- A document outlining the results of their internal fleet testing of the Weboost, more specifically preferred mounting locations by vehicle type and antenna placement.

- A general wiring schematic from fleet maintenance for each vehicle type.

AEP assembled a very well written RFP (Request for Proposal) including the information we requested above, together with details of their OPCO operating areas. Critically, Corporate Procurement made themselves available for questions and recommendations as we developed our RFP Response. AEP published a thorough RFP that included the basic elements of a deployment plan respondents should address and preliminary onboarding documentation requirements, including:

- Company Profile: consisting of business basics, mission, coverage area, and culture

- Objectives: define whether RFP is by invitation only or a broad distribution and timelines

- Background and Overview of Project: why, what, where, and when

- Project Scope: respondent’s abilities, reach, timeliness, availability, and inventory control

- Evaluation Criteria: costs, solution, installation capabilities, experience, financial stability, security standards, ability to meet timelines

- Who to Contact for Questions: technical and commercial

- How to Respond: email, physical delivery by courier, mail, etc.

- Due Date

THE RFP RESPONSE

The RFP response from your respondents should be as detailed as possible, but not too textual. Specifics of the plan are critical. Your RFP should make it very clear whether you prefer a separate written response, or a response made directly within the body of the RFP. A separate written response will give you much more detail and evaluation criteria to work with.

MOBILE responded to the RFP with a separate written response that included an executive summary to summarize our understanding of the overall need, the equipment to be installed, the time frame required, a pilot requirement, and the optional deployment plans to be considered.

MOBILE presented an RFP Response that included:

- Installation locations (with addresses and contact personnel info)

- Installation Scope of Work (equipment to be Installed and/or de-installed)

- Record keeping requirements (capturing serial numbers, VINs, etc.)

- Reporting (online Smartsheet Installation Log, and weekly PM meetings)

- Deployment Plan (tech teams, daily and weekly throughput, start & finish dates, etc.)

- Deliverable Requirements, including:

- Vehicle Completion and Acceptance Reports

- Uploads to Smartsheet

- Project Dashboard.

- Weekly invoicing

- Daily Scheduling Coordination

- Liability and Worker’s Comp Insurance (COI details)

- Installation Warranty (standard 90-day, or maximum one-year)

- Covid Policy, and Health and Wellness Precautions

- Pricing and Total Project Cost

- Pilot Acceptance Test (to confirm installation scope of work and daily throughput)

- Equipment and supplies to be provided by MOBILE.

- Equipment and supplies to be provided by AEP.

- RFP Required Document attachments (W9, Certificate of insurance)

PILOT ACCEPTANCE TEST

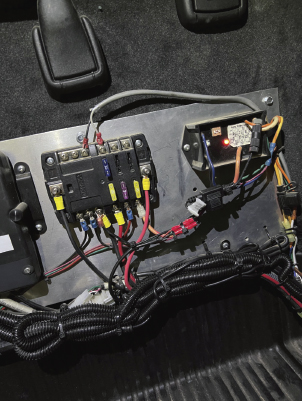

After reviewing our RPF response the Review Committee announced that our proposal had been accepted with a proviso that our recommended Pilot Acceptance Test (PAT) to test the scope of work and daily throughput of a team be moved up considerably prior to formal onboarding. The goal of the PAT is to ensure the RFP installation scope of work is generally the same for each vehicle, safety issues are identified, fleet management personnel agree to the methodology and installation techniques required for a professional and consistent installation for all vehicles.

The PAT also provides the opportunity to test our cloud-based Smartsheet Installation Log and project Dashboard for accuracy, speed, and formatting meets the fleet project management team’s requirements for installation acceptance.

What happens quite often during a PAT with a professional well-trained team, is it becomes obvious during the pilot that additional add-on work can be included to the installation scope of work that would not have otherwise been addressed until a later date.

STATEMENT OF WORK (SOW)

From what has been gathered and agreed upon from the pilot, a formal SOW is completed to include the:

- summary of the project and goals,

- step-by-step installation scope of work,

- list of equipment to be installed,

- special tools required,

- hazardous materials and safety criteria,

- Information to be captured and uploaded to the Smartsheet,

- responsibilities of all parties,

- installation acceptance criteria,

- reports to be provided,

- pricing and total cost,

- deployment plan with summary installation schedule,

- invoicing parameters and frequency,

- signatures of agreement to the SOW.

Once the SOW has been executed and agreed upon, a formal purchase order is normally required to start work which includes pricing, a reference to the signed SOW, total cost, expiration date, and where the invoicing should be sent.

INSTALLATION SCHEDULE AND ROLL-OUT

After the signed SOW was obtained, MOBILE’s project manager together with our data analytics team developed a very detailed day-to-day installation schedule by deployed team that reflected the deployment plan requirements.

Deployment plans are either sequentially designed location-by-location, OPCO by OPCO, or dynamically designed with each team working their own region or OPCO and deploying simultaneously so all OPCO locations are receiving installations simultaneously. AEP desired to complete the installations within a six-month period and felt the dynamic approach was much easier to manage and control. This proved correct as we completed the installations within four months with six deployed teams.

LESSONS LEARNED

In the end, the deployment was very successful primarily because the scope of work, deployment plan, PAT, and schedule were well defined and executed. Reporting was immediate with our live online Smartsheet so any installation or communication issues that arose could be quickly addressed by the project managers.

Our teams were treated very professionally by the AEP fleet location representatives, and their involvement was key to ensuring scheduling timelines were met and equipment made available. Since we had ongoing course corrections, when necessary, a formal end-of-project “Lessons Learned” session was not required. Instead, we are outlining new opportunities for 2024 and beyond with AEP.

We now have a long-term relationship in place with another high-quality fleet customer.

ABOUT THE AUTHOR

Ron Harris is president of Mobile Installation Technologies. Find out more at www.mobileinstallusa.com.