The commercial van market has evolved dramatically over the past decade, with businesses increasingly demanding higher payload capacities and wider equipment compatibility from their work vehicles.

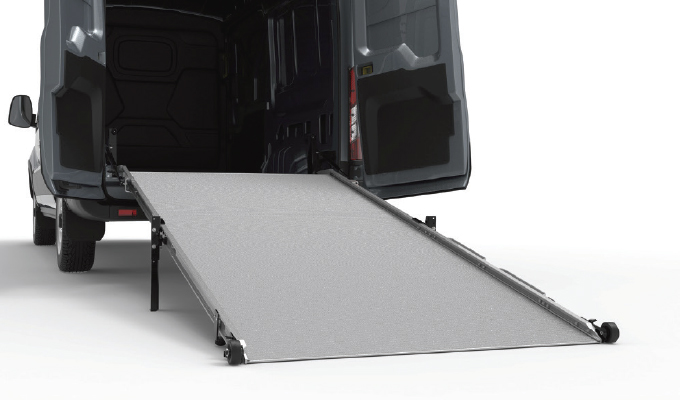

As a result, Link Manufacturing’s latest additions to its LB20 ramp family – a 47- by 126-inch model and a 51- by 126-inch model – represent a direct response to these changing market dynamics, offering upfitters a solution that combines greater load capacity with the simplicity and reliability.

“We’ve been installing Link ramps for over 20 years, and the evolution of their product line has always tracked accurately with what our customers need,” says Kevin Mulvihill, general manager, U.S. Upfitters. “These new high-capacity models will nicely complement our ramp offering, helping us reach a new segment of the market. I also love telling customers that the ramps are made in Sioux Center, Iowa, right here in the U.S.A.”

MEETING THE DEMANDS OF MODERN FLEETS

The introduction of Link’s 2,000 pound capacity ramps come at a critical time for the van upfitting industry. As businesses across sectors from landscaping to audio/visual production invest in heavier, more sophisticated equipment, the limitations of standard 1,000 to 1,500 lbs. capacity ramps have become increasingly apparent. The new models, specifically engineered for Mercedes-Benz Sprinter (47” width) and Ford Transit or Ram ProMaster (51” width) cargo vans, bridge this gap without sacrificing the fundamental advantages that make ramps superior to hydraulic liftgate alternatives.

Rob DeMars, director of operations and sales for American Bobtail, Inc., has witnessed this evolution firsthand. His company, which operates 32 bays across a 14-acre campus in Rockwall, Texas, has installed thousands of ramps over the years.

“The requests we get from customers have changed significantly,” says DeMars. “Five years ago, most were happy with standard capacity ramps. Now, with zero-turn mowers getting bigger, floor cleaning equipment becoming more robust and everyone wanting to maximize their payload, these high-capacity ramps will fill the bill.”

The engineering behind the new models remains focused on maintaining ease of use despite the increased capacity. Each ramp features dual pull-style gas-spring-assist mechanisms that reduce the lifting force required for deployment and stowing. This design consideration proves particularly valuable given the changing demographics of the commercial driver workforce.

“With older individuals and females making up an ever-increasing percentage of the workforce, the reduced lifting effort these spring-assist mechanisms provide isn’t just a convenience – it can be a necessity,” says Nick VanderKooi, advanced engineer, Link Manufacturing. “We’ve managed to increase capacity while actually improving the user experience through better weight distribution and more efficient spring placement.”

ECONOMICS OF SIMPLICITY

Unlike hydraulic liftgates, which can be costly to purchase, install and maintain, the LB20 ramps offer a lower-cost solution that extends beyond the initial purchase, encompassing the total lifecycle of the equipment.

“When I explain to fleet managers that these ramps require no hydraulic maintenance, no battery drain, no specialized training and no scheduled service intervals, you can see the lightbulb go on,” says Vinny Lamontagna, sales manager, U.S. Upfitters. “In an era where every fleet is dealing with driver shortages and vehicle downtime, having equipment that just works every time is invaluable.”

The reliability factor has proven especially compelling for high-frequency users. DeMars recalls a mobile medical service provider that initially resisted his recommendation for spring-assist ramps. After deploying 50 units without the feature, the customer’s drivers provided feedback that changed the entire procurement strategy.

“Now every one of their thousands of vans includes spring-assist ramps,” says DeMars. “The drivers told management it was the single best ergonomic improvement they could make.”

ENGINEERING FOR REAL-WORLD APPLICATIONS

The new high-capacity models incorporate several design refinements that reflect Link’s understanding of how ramps are used in the field. The 11” deep mounting plate features an expanded bolt pattern that accommodates various fastener configurations, simplifying installation across different vehicle platforms. This flexibility proves particularly valuable for upfitters working with the growing number of electric commercial vans entering the market.

“The mounting flexibility is huge for us,” says Mulvihill. “We’re seeing more variety in floor configurations, especially with electric vans. Having multiple mounting options means we can install these ramps properly without extensive modifications.”

The adjustable legs on the new models provide stability for heavier loads while maintaining a manageable deployed footprint. This feature addresses one of the key challenges in high-capacity ramp design: providing adequate support without creating an unwieldy or space-consuming solution.

Weather resistance, long a strong point of interior-mounted ramps, takes on added importance with equipment that may see decades of service. By storing vertically inside the vehicle’s cargo area, the ramps avoid constant exposure to road salt, debris and weather that degrades exterior-mounted hydraulic systems. This protection contributes to the longevity that upfitters consistently report.

“I’ve personally seen Link ramps outlast two or three vehicles,” says DeMars. “We just unbolt them from the old van and install them in the new one. Try doing that with a hydraulic liftgate.”

MARKET EXPANSION THROUGH CAPABILITY

The availability of 2,000 lbs. capacity ramps open new market segments for upfitters and their customers. Landscaping companies can now load mowers and larger equipment. Commercial cleaning services can transport ride-on floor scrubbers. A/V companies can move larger sound systems and staging equipment. The wider deck widths – 47” and 51” – accommodate equipment that simply wouldn’t fit on narrower ramps.

“We’re already seeing interest from market segments that traditionally relied on trailers or larger trucks,” says Lamontagna. “The ability to use a standard cargo van for heavy equipment transport changes the economics for many small businesses. They can reduce their fleet complexity while improving maneuverability and fuel efficiency.”

The impact extends to last-mile delivery operations, where the combination of high capacity and quick deployment proves particularly valuable. With e-commerce driving demand for larger and heavier residential deliveries, the ability to unload items safely and efficiently like commercial appliances, exercise equipment and furniture has become crucial.

PORTFOLIO DEPTH SUPPORTS DIVERSE NEEDS

The standard LB20 line continues to serve most cargo handling needs with capacities up to 1,500 lbs. across nine different size configurations. The LSR90 swivel ramp provides flexibility for applications requiring side access or complete cargo area clearance. The LB10 side door ramps maximize efficiency for cargo van and other vehicles, while the LT30 extended ramps offer lower approach angles for wheeled equipment.

“Having this range of options lets us be consultative with customers,” says Mulvihill. “We’re not trying to force-fit one solution. Whether they need the new 2,000 lbs. capacity, a swivel design for tight spaces, or a basic 1,000 lbs. ramp for occasional use, we can specify exactly what works best.”

This portfolio approach reflects an understanding that van upfitting isn’t a one-size-fits-all proposition. Different industries, different vehicles, and different use cases demand different solutions. By maintaining a comprehensive range while pushing the envelope with new high-capacity options, upfitters can address virtually any cargo access challenge.

A GRADUAL ASCENT

As commercial vehicles become more sophisticated and businesses demand greater versatility from their fleets, the role of simple, reliable cargo access solutions becomes even more critical.

“What excites me most about these new ramps isn’t just their specifications,” says VanderKooi. “It’s what they represent for our customers’ customers – the end users who rely on this equipment every day. We’re giving them tools that make their jobs easier, safer, and more efficient.”

As the commercial van market continues its rapid evolution, one thing remains constant: the need for reliable, cost-effective cargo access solutions that just work.

for more information

To learn more, visit www.linkramps.com.